TM 9--2815--247--34

0069 00--8

PISTONS, RINGS, AND ASSOCIATED PARTS REPAIR -- CONTINUED

0069 00

Inspection -- Continued

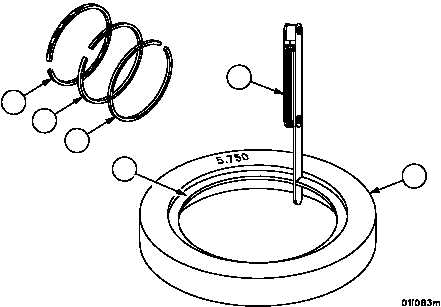

12. Place each ring (1, 2, 3, or 4), one at a time into the appropriate ring gauge (23).

NOTE

Ring gauges are identified according to ring size. Some

gauges are duel purpose tools, i.e., each side for a differ-

ent size ring.

13. Measure end gap of each ring with thickness gauge (24). Replace rings that do not meet the following limits.

REF

NO.

POINT OF MEASUREMENT

SIZES AND FITS OF NEW PARTS

inches(mm)

WEAR

LIMITS

1

2

Gap clearance of top compression and

second groove ring when fitted in

gauge

0.0400 (1.016)

0.0500 (1.27)

None

3

Gap clearance of intermediate com-

pression ring when fitted in gauge

0.0300 (0.762)

0.0400 (1.016)

None

4

Gap clearance of oil control ring when

fitted in gauge

0.0200 (0.508)

0.0400 (1.016)

None

Figure 8

23

4

3

2

1

24

|

|