ARMY TM 9-2815-253-24

AIR FORCE TO 38G1-93-2

MARINE CORPS TM 2815-24/3

3-13.2. Inspection.

a.

Inspect pump housing for cracks, corrosion, or any other damage.

b.

Inspect shim pack for corrosion or damage.

c.

Inspect tappet for cracks, corrosion, or any other damage.

3-13.3. Test.

NOTE

This test must be performed with engine installed in end item.

a.

Disconnect fuel injector pipe from top of pump to be tested.

b.

Connect a fuel pressure gage capable of displaying 3000 psi (20,685 kPa).

c.

Using end item controls, crank engine and observe pressure gage.

d.

Pressure gage should read approximately 3000 psi (20,685 kPa). If reading is not as specified, replace fuel

pump.

e.

Remove pressure gage and connect fuel injector pipe. Tighten coupling nut to 21.0 ft-lbs (28.5 Nm).

3-13.4. Installation.

a.

Remove all caps/covers.

b.

Before installing fuel injection pump, ensure governor is correctly adjusted. Refer to paragraph 3-23.5.

CAUTION

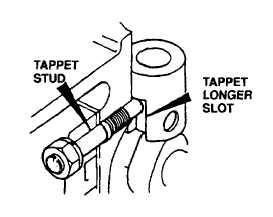

Under no circumstances must any attempt be made to remove fuel pump tappet stud from

crankcase, to prevent damage to engine block.

c.

If tappet (7, FIGURE 3-7) and thrust cup (8) were removed, install them as follows:

(1)

Tappet is installed in crankcase using long nosed pliers held open against top inside edge of tappet recess.

(2)

Submerge tappet in dean engine lubricating oil (MIL-L-2104).

(3)

Insert tappet in crankcase with longer slot facing outward to ensure it is correctly located over tappet stud.

Refer to FIGURE 3-8. Install thrust cup (8, FIGURE 3-7).

FIGURE 3-8. Fuel Pump Tappet and Stud

3-21

|

|