ARMY TM 9-2815-253-24

AIR FORCE TO 38G1-93-2

MARINE CORPS TM 2815-24/3

3-32. MAIN BFARING HOUSING.

3-32.1. Removal.

a.

Drain engine lubrication system. Refer to end item maintenance manual.

b.

Remove flywheel housing. Refer to paragraph 3-31.1.

c.

Remove crankcase door. Refer to paragraph 3-20.2.1.

CAUTION

Failure to remove a center bearing tube may result in distorting it making it difficult to remove at a

later stage.

d.

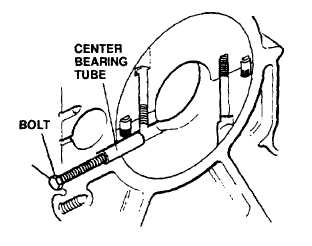

Use an intake manifold bolt to remove center bearing tube (1, FIGURE 3-40). Leave bolt in tube until it is

installed to ensure tube is installed correct way. Refer to FIGURE 3-39.

FIGURE 3-39. Center Bearing Tube

e.

Remove five capscrews (2, FIGURE 3-40) securing main bearing housing (3).

f.

Remove bearing housing (3). If it is tight, use two recesses in 3 o'clock and 9 o'clock positions and pry it off with

a suitable screwdriver. Remove and discard shim (4).

NOTE

Thrust bearing (5) will come out with main bearing housing.

g.

Remove thrust bearing (5).

h.

Clean all traces of old shim and compound from housing and crankcase.

i.

Using suitable driver, drive oil seal (6) from housing (3) taking care not to damage bearing (7).

j.

Remove bearing (7) from housing (3) as follows:

(1)

Mount housing (3) in a soft-jawed vice.

(2)

Place bolt of main bearing tool (317-50111) through plain dolly. Refer to FIGURE 3-41.

(3)

Install bolt and dolly into bearing (7, FIGURE 3-40) from oil seal side (crankcase outside face).

(4)

Install bridge over bolt threads until two legs are against housing face.

(5)

Install spacer and nut onto bolt.

(6)

Use a suitable wrench to tighten nut until bearing shells (7) are withdrawn.

3-66

|

|