|

|

|

|

|

ARMY TM 9-2815-254-24

AIR FORCE TO 38G1-94-2

b.

Inspect crankshaft and bearings as follows:

(1) Inspect crankshaft journal surfaces and crankpin surfaces for excessive wear and damage.

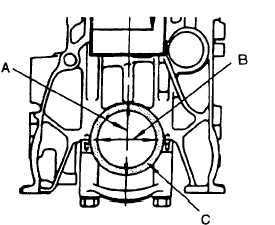

A - Main Bearing Inside Diameter

B - Crankshaft Journal Diameter

C - Crankshaft Journal to Main Bearing Clearance

FIGURE 3-84. Basic Dimension Measurements

(2) Inspect front and rear oil seal fitting surfaces of crankshaft for excessive wear and damage.

(3) Replace or repair crankshaft if any excessive wear or damage is found.

Compressed air used for cleaning can create airborne particles that

may enter the eyes. Pressure will not exceed 30 psig (207 kPa). Eye

protection required.

(4) Inspect oil ports of crankshaft for obstructions. Use air pressure to clean oil ports.

c.

Check crankshaft run-out as follows:

(1) Place crankshaft on V-blocks.

(2) Set an inside micrometer to center of crankshaft journal, refer to FIGURE 3-85.

3-135

|

|

|

|

|

Privacy Statement -

Copyright Information. -

Contact Us