ARMY TM 9-2815-255-24

AIR FORCE TO 38G1-95-2

MARINE CORPS TM 2815-24/4

Warning

If nuts (16), FIGURE 3-41) are removed prior to shat/gear separation, fuel Injection pump will fall

out which can cause personal Injury and/or equipment damage.

I.

Loosen three nuts (16, FIGURE 3-41) several turns to permit pump shaft/drive gear separation.

m.

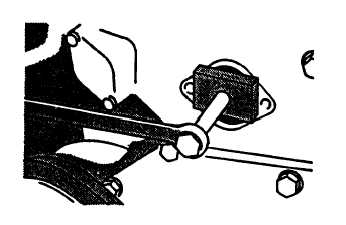

Tighten large hex head capscrew on puller clockwise until drive gear is held firmly against front plate.

FIGURE 3-44. Separating Gear and Shaft

n.

Support weight of fuel injection pump (19) and remove three nuts (16), lockwashers (17), and washers (18)

securing pump. Remove pump (19).

o.

Remove puller from drive gear.

p.

Cover all openings in pump and place pump in a clean area.

327.2. Disassembly.

327.2.1. General.

Warning

Compressed air used for cleaning can create airborne particles that may enter the eyes. Pressure

will not exceed 30 psig (207 kPa). Eye protection required.

Before commencing disassembly of pump, cover inlet and outlet holes. Remove all external grease and dirt by washing

pump with diesel fuel and blowing dry with filtered compressed air. To prevent dirt from entering fuel system, it is

essential that a clean work space, clean tools, and clean hands be used. During disassembly, remove and tag all seals,

gaskets, insulating washers, preformed packings, and lockwashers to aid in identifying replacement parts. A clean pan

should be available to place parts in during disassembly. A clean deep pan with rounded corners and filled with clean

diesel fuel or calibrating oil must be available to flush parts.

3-81

|

|