ARMY TM 9-2815-255-24

AIR FORCE TO 38G1-95-2

MARINE CORPS TM 2815-24/4

CAUTION

Do not handle precision machined rotor surfaces. Damage due to corrosion could occur.

NOTE

In addition to the parts supplied with the repair kits, cam (17, FIGURE 3-45), delivery valve stop

(35, FIGURE 3-52), and connector assembly (1, FIGURE 3-45) must be replaced during assembly.

NOTE

Parts which must be replaced and are not included in the repair kits are lockwashers, delivery

valve stop (35, FIGURE 3-52), insulator washers (15, FIGURE 3-45), and pilot tube (1, FIGURE 3-

52).

a.

Rinse rotor thoroughly in clean diesel fuel or calibrating oil.

b.

Place rotor on weight retainer (31, FIGURE 3-52) and secure in a vise.

NOTE

Do not mistake slight interference of retractor collet in bore for delivery valve sticking. If valve is

not secured straight and tight in retractor collect, collet diameter can drag in rotor bore.

c.

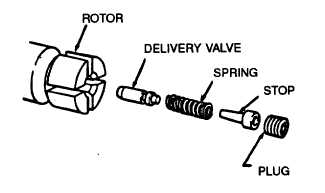

Using extractor (13383), install delivery valve (35) into bore of rotor. Ensure it slides freely in its bore, refer to

FIGURE 3-72.

FIGURE 3-72. Delivery Valve Replacement

CAUTION

Always use a new delivery valve stop (33, FIGURE 3-52). Installation of a used stop can result In

leakage and low output at cranking speed.

3-101

|

|