ARMY TM 9-2815-255-24

AIR FORCE TO 38G1-95-2

MARINE CORPS TM 2815-24/4

CAUTION

Do not use gasoline, kerosene, or commercial solvents to clean liners. Solvents will not remove

all the abrasives from liner walls.

e.

Thoroughly clean liner ID with a 50 percent solution of hot water and liquid detergent.

f.

Rinse thoroughly and wipe dry with a clean, dry rag.

g.

Swab out liner as many times as necessary with clean SAE 10W engine lubricating oil (MIL-L-2104).

h.

Continue to clean liner until a clean, white rag shows no discoloration.

i.

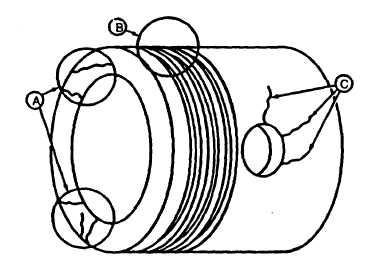

Look for fine cracks in piston head, refer to FIGURE 3-128.

i.

Inspect for bent or broken ring lands.

k.

Inspect inner and outer ends of piston pin bore for cracks in skirt.

FIGURE 3-128. Piston Inspection

l.

If the original machining marks are not visible, or the piston skirt is worn to depth of original machining marks,

replace both piston and liner. If any defects are found, replace piston and liner as a matched set. If no defects

are found, proceed to next step.

m.

Check top ring groove using a new piston ring and feeler gage, refer to FIGURE 3-129. Ring groove clearance

must not exceed 0.008 inch (0.20 mm) when measured between top of ring and ring land. If ring groove is worn,

replace piston and liner as a matched set. If ring groove is good, proceed to next step.

3-190

|

|