ARMY TM 9-2815-255-24

AIR FORCE TO 38G1-95-2

MARINE CORPS TM 2815-24/4

NOTE

Some piston pin bores are elliptical, the width being 0.0015 inch (0.038 mm) larger than the bore

specifications.

r.

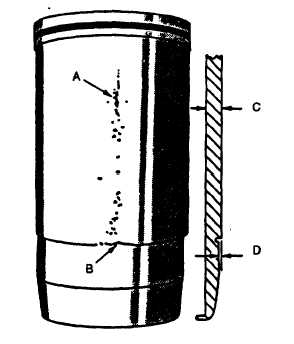

Inspect exterior length of liner for pitting (A, FIGURE 3-131). Check packing step for erosion (B). If pitting or

erosion is observed, measure depth of pits and erosion with a fine wire or needle. Replace liner if (C) depth of

any pit is one-half or more of liner thickness, or (D) depth of erosion is one-half or more of the packing step. If no

defects are found, proceed to next step.

NOTE

If pitting has occurred, check condition of coolant.

NOTE

Liners are reusable if depth of pits or erosion is less than amount specified. When installing

reusable liners, rotate 90 degrees from original position. The liners should be deglazed and new

ring sets installed on pistons, refer to paragraph 3-47.1.

FIGURE 3-131. Inspecting Cylinder Liner Pitting

s.

Carefully examine cylinder liner for signs of fatigue, such as fine cracks in flange area (A, FIGURE 3-132) and

cracks in the ring travel area (B). If any defects are found, replace the piston and liner. If no defects are found,

proceed to next step. If pistons and liners have passed all previous checks, proceed to check both for proper

specifications, listed in steps t and u.

3-192

|

|