ARMY TM 9-2815-255-24

AIR FORCE TO 38G1-95-2

MARINE CORPS TM 2815-24/4

f.

Check field windings of yoke for wear or damage. Check all connections for clean and tight solder joints.

g.

Measure brush length. If less than 0.51 inch (13 mm), replace brush holder and/or yoke assembly.

h.

Check brush springs for damage or corrosion. If damaged or corroded, replace brush holder.

i.

Check that overrunning clutch rotates freely in direction of starter rotation and that it will be locked when trying to

rotate in opposite direction.

3-12.5. Test.

3-12.5.1 Testing Starter Motor (Installed).

a.

Make sure batteries are fully charged and that all battery and starter cables are serviceable and properly

installed.

b.

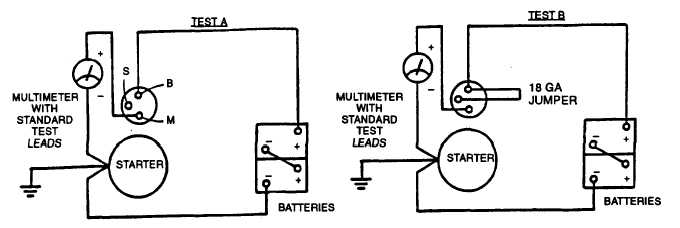

Set multimeter for DC volts, and connect as shown in FIGURE 3-18, Test A. If voltage is indicated solenoid is

defective.

FIGURE 3-18. Starter Solenoid Test Circuit

c.

Momentarily connect a jumper as shown in FIGURE 3-18, Test B. Multimeter should indicate battery voltage and

starter should crank the engine. If multimeter does not read battery voltage, the solenoid is defective. If

multimeter indicates battery voltage, but starter does not operate, starter is defective.

3-12.5.2 Testing Starter Components (Removed).

a.

Using a growler tester, place armature on it and hold a hack saw blade against armature core while slowly

rotating armature. A short circuited armature causes blade to vibrate and be attracted to core. An armature

which is short circuited must be replaced.

b.

Set multimeter for ohms and touch one probe to a commutator segment and other one to armature core, refer to

FIGURE 3-19. There should be no continuity. If there is continuity, armature is grounded. Replace armature if

grounded.

3-39

|

|