ARMY TM 9-2815-256-24

AIR FORCE TO 38G1-96-2

MARINE CORPS TM 2815-24/5

c.

Measure camshaft thrust plate clearance as follows:

NOTE

Thrust plate clearance determines camshaft end play.

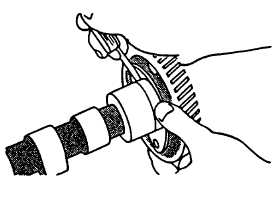

(1) Check thrust plate clearance using a feeler gage, refer to FIGURE 3-130.

(2) New part clearance is 0.003 to 0.009 inch (0.08 to 0.23 mm). Maximum allowable clearance is 0.015 inch

(0.38 mm). Replace parts as necessary.

FIGURE 3-130. Measuring Thrust Plate Clearance

d.

Measure camshaft journals as follows:

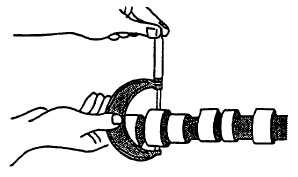

(1) Use a micrometer to take measurements, refer to FIGURE 3-131.

(2) New camshaft journal diameter is 2.200 to 2.201 inches (55.87 to 55.90 mm). Maximum wear tolerance is

0.001 inch (0.025 mm).

(3) If a camshaft journal diameter is less than 2.199 inches (55.85 mm), install a new camshaft.

(4) Measure camshaft bearing bore diameter in cylinder block; 2.204 to 2.205 inches (55.98 to 56.01 mm).

Maximum clearance between bore and camshaft journal; 0.007 inch (0.18 mm).

FIGURE 3-131. Measuring Camshaft Journals

e.

Measure camshaft lobe height as follows:

(1) Measure each camshaft lobe at highest point and at narrowest point, refer to FIGURE 3-132. Subtract

narrowest dimension from highest dimension to find camshaft lobe height. If height is not correct on any

lobe, install a new camshaft.

3-171

|

|