ARMY TM 9-2815-256-24

AIR FORCE TO 38G1-96-2

MARINE CORPS TM 2815-24/5

i.

Install through bolts (19) and tighten evenly 50 to 60 in-lbs (5.65 to 6.78 Nm).

j.

If necessary, remove through bolts (19) and (20) and stator (22) to align housings as match marked on

disassembly. Reinstall bolts and torque evenly 50 to 60 in-lbs (5.65 to 6.78 Nm).

k.

Insert strap (14) of rectifier bridge (18) through slot in diode-trio (17) body. Bend strap (14) over B+ terminal and

secure with cone washer (13) and nut (12).

I.

Apply thin film of heat sink compound (5202217) to back of rectifier bridge (18) and mating area of rear housing

(20)

m. Install diode-trio (17) and rectifier bridge (18) on rear housing (20) with bolts (16) and connect stator leads with

screws (15). Remove tags.

n.

Install voltage regulator (11) to rear housing (20) with insulating washers (10) and bolts (9).

o.

Install brush assembly (8) and strap (7) with nuts (6) and washer (33).

p.

Position felt gasket (5) in back cover (4) and install back cover on rear housing (20) with bolts (3).

q.

Install terminal washers (2), terminal nuts (1), and jumper (18, FIGURE 3-5).

r.

Perform battery charging alternator performance test as follows:

(1)

Mount battery charging alternator on test fixture capable of providing 5000 alternator rpm.

CAUTION

Make sure connections are tight to avoid possible damage to instruments, battery charging

alternator, or wiring due to short circuits.

(2)

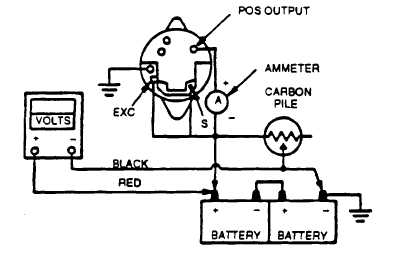

Set up test circuit as shown in FIGURE 3-13.

FIGURE 3-13. Battery Charging Alternator Test Circuit

NOTE

Carbon pile and ammeter must be capable of handling the alternator rated output.

(3)

Starting with the carbon pile off, slowly increase load while observing ammeter and maintaining 5000 rpm.

Increase load until an output voltage of 27.0 to 29.0 VDC is achieved. Record the output current at this

point. Acceptable current is 38 amperes at 70 to 80°F (21.1 to 26.7°C).

Change 3

3-34

|

|