ARMY TM 9-2815-256-24

AIR FORCE TO 38G1-96-2

MARINE CORPS TM 2815-24/5

i.

If defective, remove screw (18) securing strap (19) to engine; remove strap.

j.

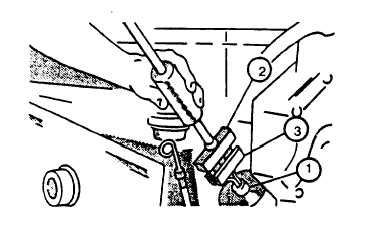

Remove oil filter nipple (12) from cylinder block with a suitable pilot bearing puller, refer to FIGURE 3-47.

k.

Cover all openings.

FIGURE 3-47. Removing Oil Filter Nipple

3-16.2. Inspection.

a.

Inspect hoses for cracks, brittleness, or any other defects. Replace as necessary.

b.

Inspect relief valve for damage. Replace as necessary.

WARNING

Compressed air used for cleaning can create airborne particles that may enter the eyes. Pressure

will not exceed 30 psig (207 kPa). Eye protection required.

c.

Inspect coolant passage through cooler for a restriction caused by scale or sludge. Use compressed air and blow

through passage to make sure it is open. If engine lubricating oil was contaminated with metallic particles,

discard oil cooler.

3-16.3. Installation.

NOTE

Remove all covers.

a.

Install oil filter nipple (12, FIGURE 3-46) in engine block as follows:

(1)

Put oil filter nipple over its bore in cylinder block. Turn oil filter nipple so oil hole is as low as possible, refer

to FIGURE 3-48.

Change 3

3-63

|

|