ARMY TM 9-2815-259-24

AIR FORCE TO 38G1-125-2

MARINE CORPS 09249A/09246A-24

5-97

(a)

Inspect each piston orifice (1, Figure 5-79) to make sure it is not plugged or damaged.

Cooling orifices deliver approximately 0.4 gallon per min (1.50 liters/min) oil flow.

(b)

Use soft wire brush and compressed air to clean orifice. Replace if condition is

questionable.

CAUTION

A piston cooling orifice failure could cause damage to piston, piston pins,

rod pin bushings, and liners. If a piston cooling orifice is left out of

assembly, low or no oil pressure will result.

(c)

Inspect all passages and crevices to ensure they are cleared of sludge and grease.

(d)

Inspect all coolant passages to ensure they are cleared of any lime deposits and scale.

CAUTION

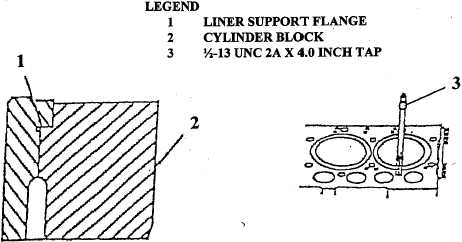

Do not file line support flange excessively. Excess filing can damage liner

support flange and may result in an improper fit. Thoroughly clean all

filings from cylinder block (2, Figure 5-81). Failure to comply may result in

engine damage.

(e)

Be sure liner support flange (1, Figure 5-81) is free of any burrs. If burrs are present, use a

small half-moon file and lightly file (in a circular motion) burr off at approximately 60

degree angle. Do not let file hit top of cylinder block while filing.

FIGURE 5-81. INSPECTING CYLINDER BLOCK

(f)

Carefully inspect cylinder block for cracks or damage. Replace block of there is evidence

of physical damage.

|

|