ARMY TM 9-2815-259-24

AIR FORCE TO 38G1-125-2

MARINE CORPS 09249A/09246A-24

5-98

(g)

When determined that cylinder block is serviceable, clean out threads for cylinder head

capscrews in top deck of cylinder block using 1/2-13 UNC-2A x 4.00 inches (101.6 mm)

long tap (3). Use compressed air to remove any debris or fluid which may be present in the

tapped holes after cleaning.

(h)

Inspect O-ring bore. If required, clean O-ring bore using O-ring bore cleaning brush as

follows:

1

Chuck bore cleaning brush in 1/2 inch drill motor. Rotate brush and move in an up

and down motion in O-ring bore.

2

Thoroughly clean all lime deposits from O-ring bore.

(3)

Test the cylinder block to confirm that it is within specifications. Perform testing using the

following steps:

NOTE

The cylinder block measurements must be made with the main bearing caps

installed.

(a)

Before assembly of main bearing caps, identify markings and ensure caps are reinstalled in

their original position. Refer to paragraph 5.4.4. Install main bearing caps (without

bearings) in cylinder block and tighten to 100 lb-ft (135 Nm).

(b)

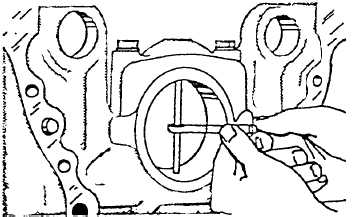

Measure main bearing bore diameter, refer to Figure 5-82. Refer to Table 5-11 for

specifications.

(c)

Measure engine block main thrust bearing width. Refer to Table 5-5 for specifications.

(d)

If bearing caps are damaged, or bore is not within specifications, replace cylinder block.

FIGURE 5-82. MEASURING MAIN BEARING BORE

|

|