TM 9-2920-243-34

MACK Model ENDT 673 engines.

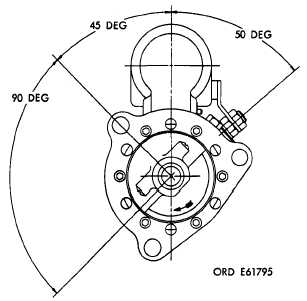

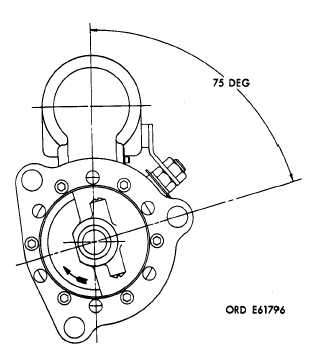

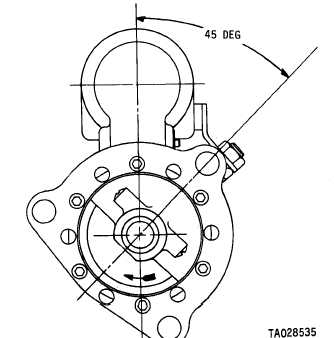

However, the pinion housing is positioned

differently for certain engine application.

Figure 3-40 illustrates position for LDS-

465-1, LDS-465-lA and MACK Model

ENDT 673 engine applications, figure 3-

41 illustrates position for LD-465-1, LD-

465.lC and LDT-465-lC engine ap-

plications, and figure 3-42 illustrates

position for LDS-465-2 engine ap-

plications.

Figure 3-42. Pinion housing position for LDS-465-2 engine

application.

3-25. Installation of Solenoid Relay Assembly

a. Place relay assembly (C, fig. 3-4) on field

Figure 3-40. Pinion housing position for LDS-456-1,

LDS-465-1A and MACK Model ENDT 673 engine applications.

Figure 3-41 Pinion housing position for LD-465-1, LD-465-lC

and LDT-465-1C engine applications.

ring and guide shaft, and insert assembly (fig. 3-

9) through seal in relay cover. Make certain shaft

enters plunger so threaded end of shaft is alined

with hole in plunger.

b. Insert shaft adjusting tool (A, fig. 3-4) and

engage end of tool with end of adjusting shaft.

Turn tool clockwise to engage plunger with shaft

and insert assembly (fig. 3-9). Turn tool eight

complete turns.

c. Move relay so that it alines with mounting

holes in field ring and secure with two hex-head

bolts (A, fig. 3-3).

d. Using shaft adjusting tool (A, fig. 3-4) turn

adjusting shaft clock wise eight additional turns.

e. Apply 24 volts direct current across ter-

minals 1 and 3.

NOTE

Terminals are numbered with raised

numerals on the relay cover.

CAUTION

Never leave relay energized any longer

than necessary to check clearance. Also,

never make adjustment when relay is

energized.

f. Refer to figure 3-43. Gently push drive

assembly back against arm and measure

3-18

|

|