| Tweet |

Custom Search

|

|

|

||

TM 9-8000

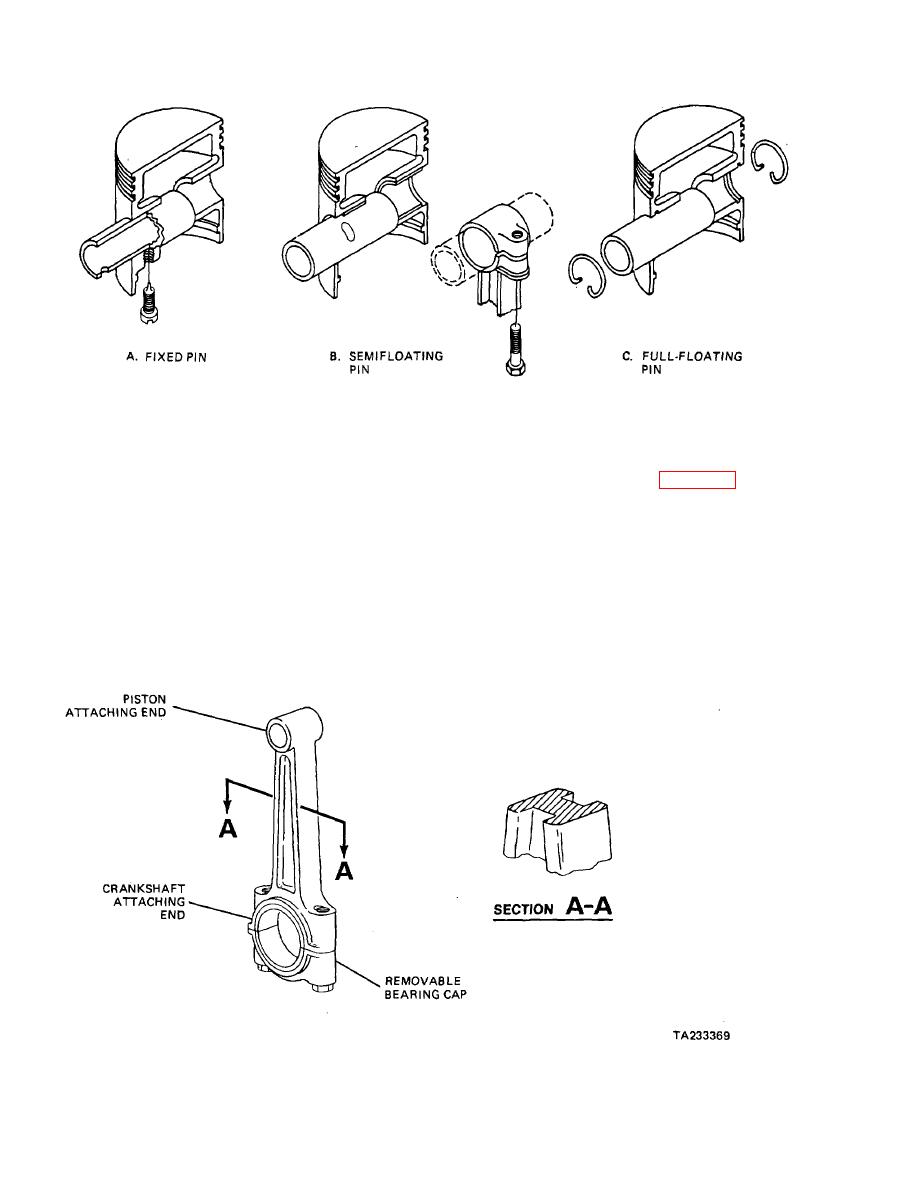

Figure 3-32. Piston Pin Configurations.

that it is made with offset throws. The weight of the

heavy crankshaft construction and sufficient support

throws tend to make the crankshaft rotate elliptically.

along its length by bearings.

This Is aggravated further by the weight of the piston and

(3) Torsional Vibration (Fig. 3-37). Torsional vibration

the rod. To eliminate the problem, weights are positioned

along the crankshaft. One weight is placed 180 degrees

occurs when the crankshaft twists because of the power

away from each throw. They are called counterweights

stroke thrusts. It Is particularly noticeable on engines with

and are usually part of the crankshaft, but may be

long crankshafts, such as In-line engines. It is a major

separate bolt-on items on small engines.

reason why in-line, eight-cylinder engines are no longer

produced. The vibration is caused by the cylin- ders

(2) Vibration Due to Deflection. The crank-

furthest from the crankshaft output. As these cylinders

shaft will have a tendency to bend slightly when

apply thrust to the crankshaft, it twists, and as the thrust

subjected to the tremendous thrust from the piston. This

decreases, the crankshaft unwinds. The twisting and

deflection of the rotating member will cause a vibration.

unwinding of the crankshaft produces a vibration. The

This

vibration

is

minimized

by

use of a

Figure 3-33. Connecting Rod Construction.

3-19

|

||

|

||