| Tweet |

Custom Search

|

|

|

||

TM 9-8000

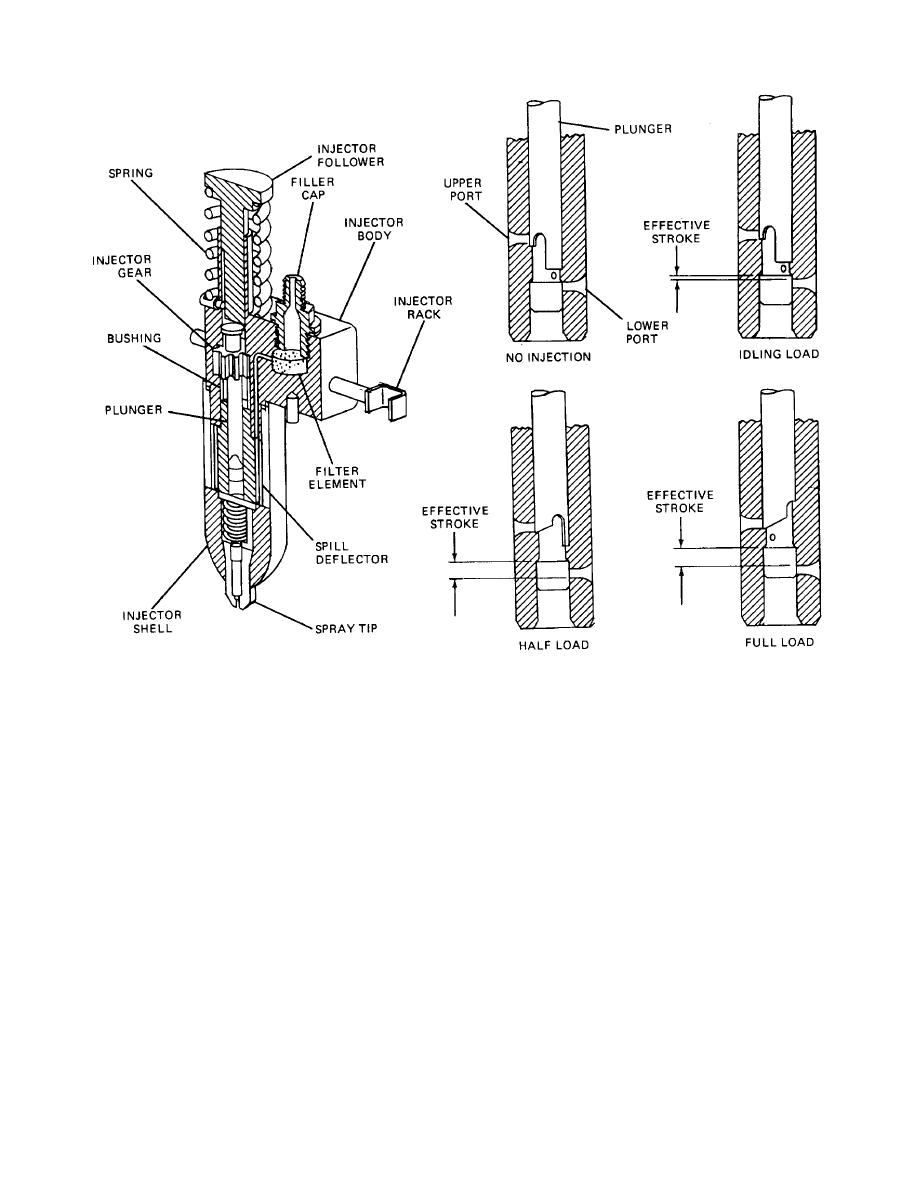

Figure 5-15. Unit Injector Operation

in the cylinder head with their spray nozzles protruding

at different heights. The plunger operates up and down

into the combustion chamber. A clamp, bolted to the

in the bushing bore.

cylinder head and fitting into a machined recess in each

side of the injector, holds the injector in place in a water-

(3) The plunger is actuated by a camshaft that

cooled copper tube that passes through the cylinder

is built right into the engine. The operation takes place

head. The tapered lower end of the injector seats in the

through a rocker arm and a push rod. The push rod has

copper tube, forming a tight seal to withstand the high

a roller-type cam follower and is spring loaded to prevent

pressures inside the cylinder. The injector operates as

component damage in the event of injector nozzle

follows:

clogging.

The plunger is situated under a follower.

This follower is spring loaded to make it follow the

(1) Fuel is supplied to the injector through the

camshaft.

filter cap. After passing through the fine grained filter

element in the inlet passage, the fuel fills the annular-

(4) The plunger can be rotated in operation

shaped supply chamber that is created between the

around its axis by the gear, which is meshed to the

bushing and the spill deflector.

control rack.

Each injector rack is connected by an

easily detachable joint to a lever on a common control

(2)

The bushing bore is connected to the

tube which, in turn, is linked to the governor and the

throttle.

fuel supply by two funnel-shaped ports, one on each side

TA233451

5-20

|

||

|

||