| Tweet |

Custom Search

|

|

|

||

TM 9-8000

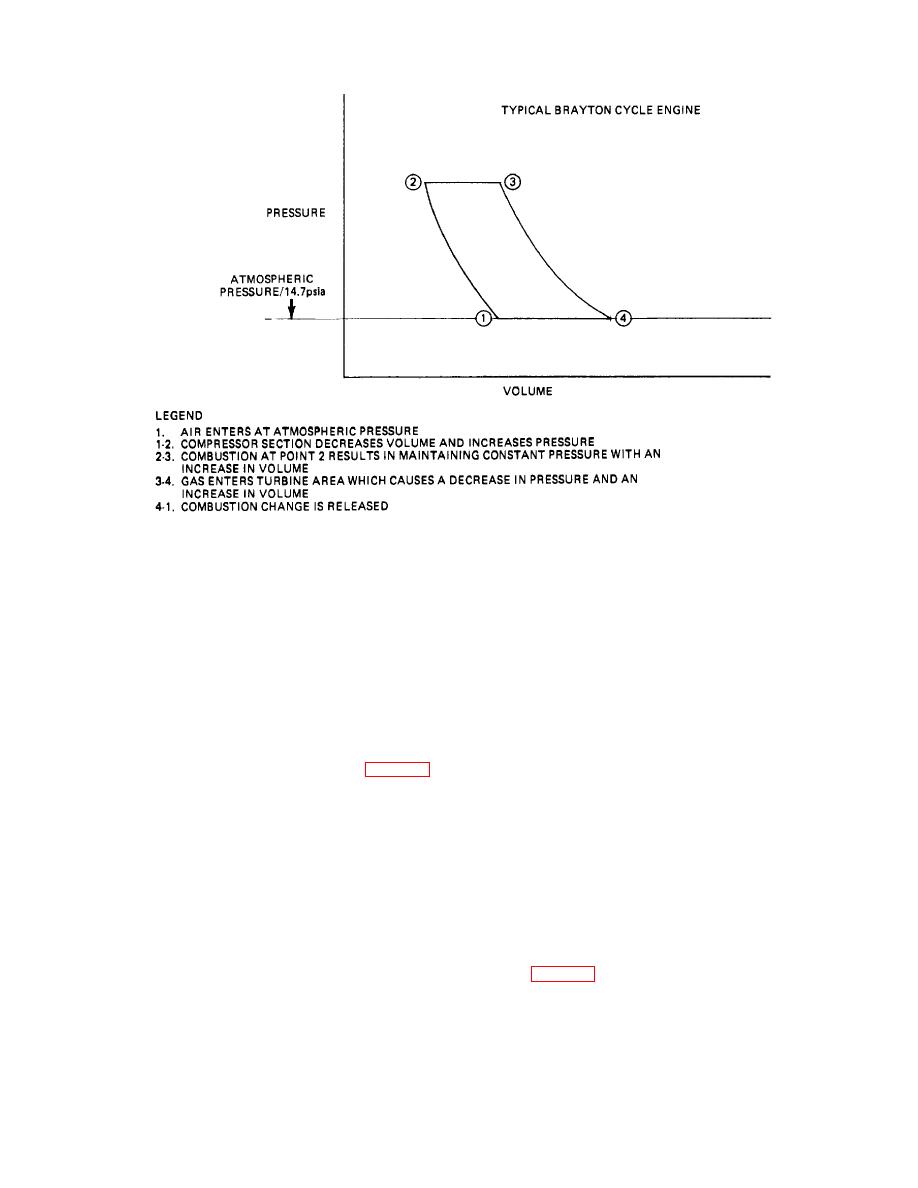

Figure 10-5. The Brayton Cycle

than the gas turbine engine.

The piston engine

the combustion chamber maintains a constant

withstands combustion chamber temperatures of

temperature and limits it to approximately 10000 to

approximately 5000F (2760C) for a short duration of

20000F (537.70 to 1093.30C). This is done to retain the

time. The hot components are cooled rapidly to maintain

resilience of internal components and inhibit formation of

relatively low temperatures of only a few hundred

foreign

matter

on

rotating

parts.

degrees. In the gas turbine,

Section III. BASIC ENGINE STRUCTURE

chamber with the proper amount of high-pressure air,

and will result in a lack of power. Modern compressors

serves to furnish a uniform and steady airflow to the face

are able to achieve compression ratios of approximately

of the compressor. Inlet sections may be equipped with

15:1 and efficiencies approaching 90 percent. Two

or without inlet guide vanes. Inlet guide vanes serve to

common types of compressors are discussed below.

direct the air into the first stage of the compressor.

a. Axial. The axial compressor performs the

10-9. Compressors. The compressor is designed to

compression process in a straight line parallel to the axis

provide the combustion chamber with a maximum

of the engine. The axial compressor is composed of

amount of high-pressure air that is heated and expanded

rotating members called rotors and stationary members

through the turbines. The amount of energy released

called stators. A row of rotors and stators is called a

from the heated airmass is proportional directly to the

stage. The axial compressor is composed of a series of

mass of air consumed. This is the major reason why the

stages (fig. 10-7). During operation the air is arrested in

compressor is one of the most important components in

the first stage of compression and is turned by a set of

the gas turbine. A poorly designed compressor will not

stator vanes, picked up by a set of rotor blades,

provide

the

combustion

TA233507

10-6

|

||

|

||