| Tweet |

Custom Search

|

|

|

||

TM 9-8000

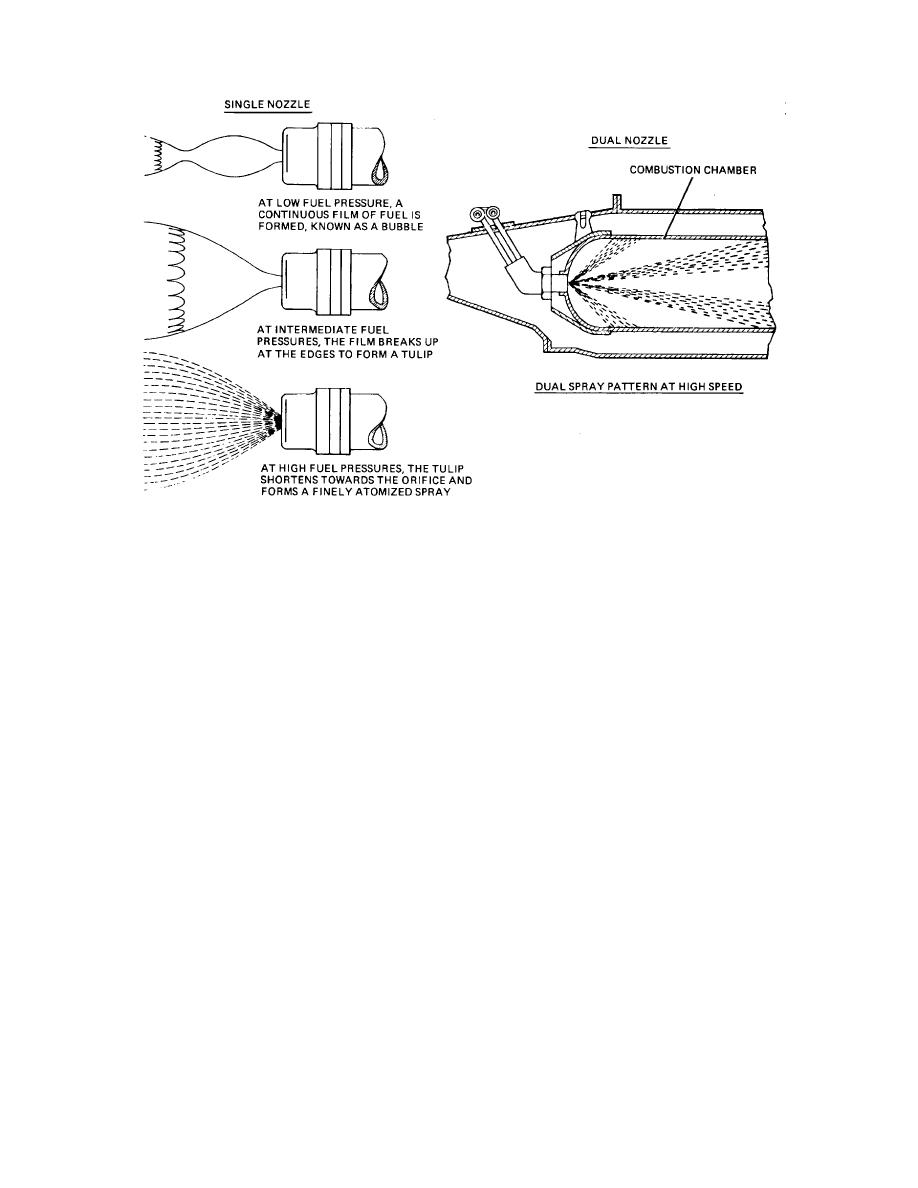

Figure 10-19. Fuel Injection Nozzles

speeds also, but as speed increases, secondary parts

the engine with the proper air-fuel ratio over a broad

are opened, allowing additional fuel to enter the

band of operating conditions.

combustion chamber. This feature provides

Section V. LUBRICATION SYSTEM

be taken in selecting an oil that will not break down under

10-17.

Requirements.

The lubrication system is

these severe conditions.

designed to clean, cool, and lubricate the internal

components of the engine. While each lubrication

10-18. Lubrication Oils. Lubricating oils used in gas

system is designed for a particular engine, certain

components are common on most systems. A wide

turbine engines must possess certain performance

variety of operating temperatures makes the design of

factors. Oils must resist foaming and provide a steady

the lubrication system even more difficult. Gas turbine

stream of oil to bearings. This ensures proper lubrication

engines operate in vehicles that can be exposed to

and cooling under all operating conditions. Mineral oil

temperatures as low as -60F (-51.1C), as well as

and synthetic oils commonly are used for lubricating

internal temperatures as high as 400F (204.4C). One

purposes in turbine engines, as discussed below.

a. Mineral Oils. Mineral oils generally are used in

severe problem experienced with gas turbine engines

occurs as the engine is stopped. A large amount of heat,

smaller, low-power engines and where temperatures do

stored in the turbine, then is transferred to the bearings.

not reach extremes. These oils generally are not used

This phenomenon raises the temperature of the bearing

because they are incapable of providing satisfactory

much higher than that encountered during operation.

performance at both very low and very high operating

The temperature of the lubricating oil, which is now

temperatures. They have been known to be extremely

stagnant around the bearing, also is greatly increased.

thick at low

Care must

TA233517

10-16

|

||

|

||