| Tweet |

Custom Search

|

|

|

||

TM 9-8000

temperature, high-altitude, or high-speed applications.

Brush arc is an explosion hazard; fuel or oil cannot be

used safely as a coolant. The rotor winding is hard to

cool and is relatively unreliable in high-speed or rough-

drive applications that cause stress on rotor windings

and insulation.

The wound-pole alternator has an

extensive history of development, but is best suited for

low- speed applications in a limited range of

environments.

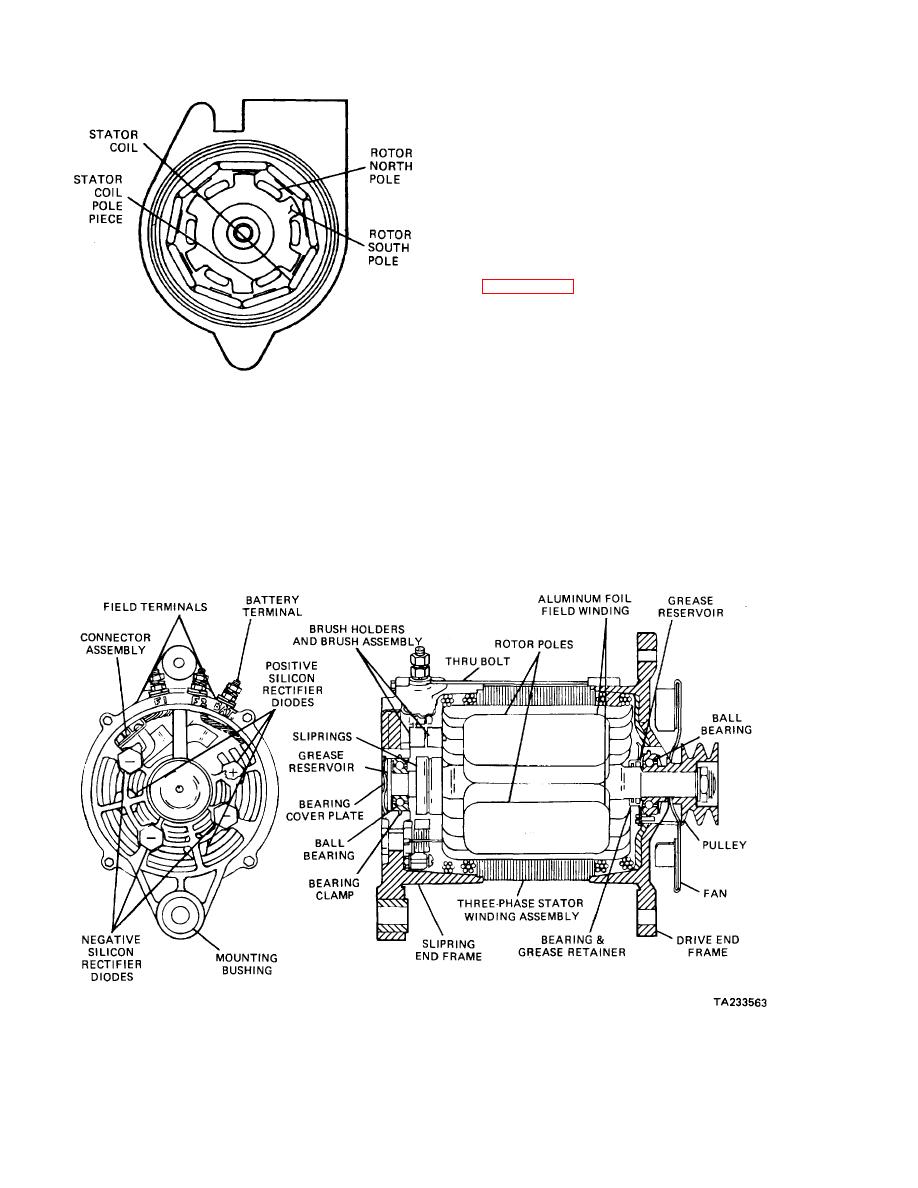

b. Lundell Alternator. The Lundell rotor, as shown in

windings around the axis of the rotor shaft, resulting in

each end of the shaft assuming a polarity. Coupled to

each end are interspaced fingers forming opposite

polarities that provide an alternating field when rotated.

Field excitation is achieved through slipring conduction.

Figure 13-27. Rotor-to-Stator Relationship.

The following are advantages of the Lundell rotor. This

rotor has a simple rotor winding construction and

polarity occurs on successive poles. Pole excitation

stationary output current windings. The disadvantages of

current is obtained through sliprings. The advantages of

the Lundell rotor are windage (air resistance) losses and

the wound-pole alternator are a wide speed range:

the use of sliprings and brushes.

output current windings are stationary, and sliprings carry

low field excitation current.

The following are

c. Lundell Inductor. This generator type differs from

disadvantages of the wound-pole alternators: Brushes

the previously described Lundell type, in

and sliprings wear, are affected by contamination,

produce contaminating carbon dust, may cause voltage

modulation, and are not reliable for high-

Figure 13-28. Wound-Pole Alternator.

13-27

|

||

|

||