| Tweet |

Custom Search

|

|

|

||

TM 9-8000

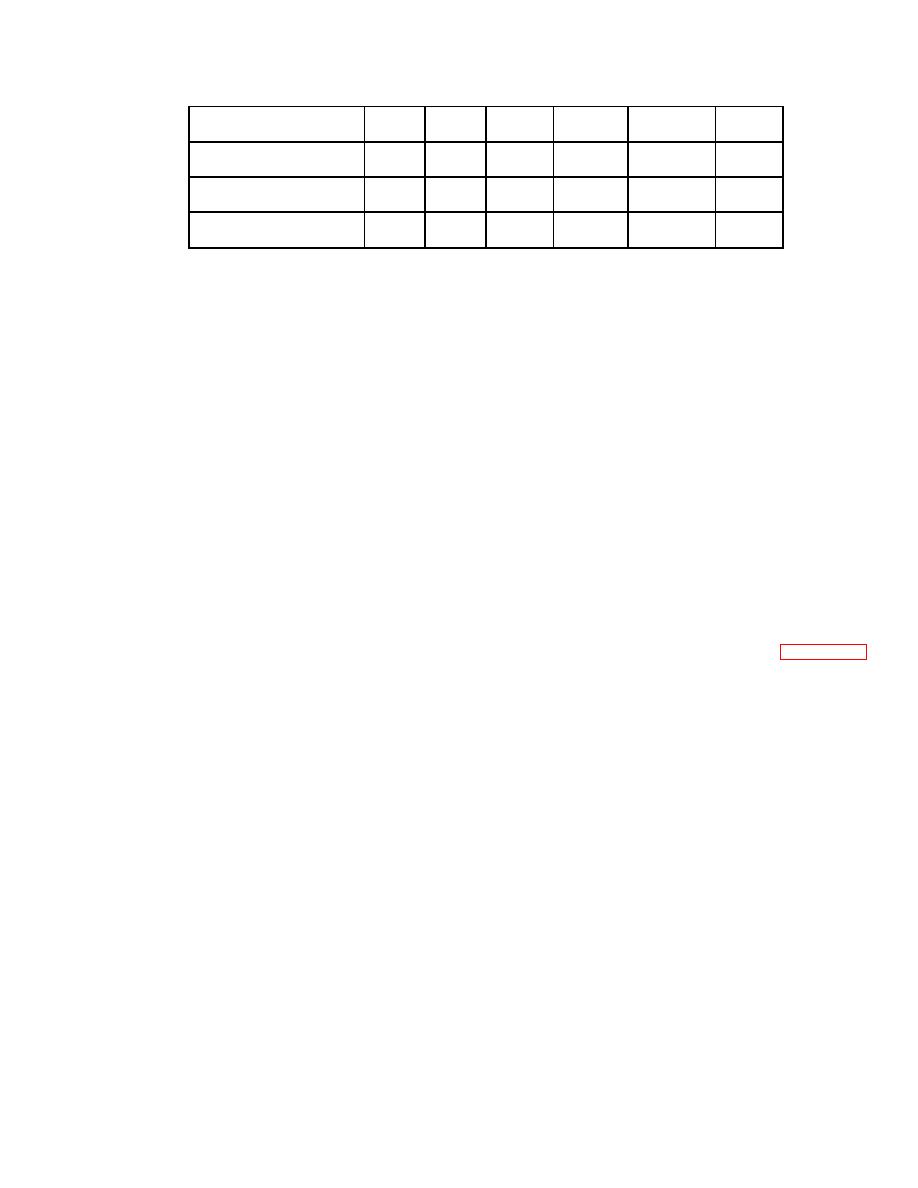

CONDITION

1

2

3

4

5

6

SUN GEAR

H

H

T

I,R

I

T

PINION CARRIER

T

L

L

H

T

H

INTERNAL GEAR

I

T

H

T

H

L,R

H - HOLD

I - INCREASE OF SPEED

T - TURN

L - REDUCTION OF SPEED

R - REVERSE

Figure 19-7. Laws of Planetary Gearing

only do the bearings provide support, but they also serve

(ball, roller, or needle bearings). Bronze bushings are

to reduce the friction between the moving parts.

used extensively for piston pin bushings in internal

combustion engines.

a. Sleeve-Type Bearings. These include bearings

b. Thrust Washers. A thrust washer is a form of

for rotating parts and for parts that merely slide over each

friction bearing designed to limit lateral movement.

other without turning. Most of the bearings of the

These washers generally are placed between moving

mechanisms described in this section are for rotating

parts or one moving part and a stationary member. They

parts. However, two examples of bearings for parts that

generally are not designed to absorb thrust constantly, as

do not rotate relative to each other are the shifter shafts

overheating can occur. Thrust washers generally are

in transmissions, which merely slide endwise in holes in

made of bronze or hardened steel.

the case, and the slip joints of propeller shafts.

The simplest type of sliding surface bearing applied to a

19-8. Ball and Roller Bearings (Antifriction). These

rotating part is one in which an accurately finished shaft,

bearings are used throughout automotive power

or journal, rotates in an accurately finished hole without

transmission systems. The usual locations of antifriction

any bushing, the two being separated by an oil film.

bearings in a truck chassis are shown in figure 19-8.

Such bearings may be used for differential pinions; the

They are known as antifriction bearings, because friction

holes are in the rotating pinions, which turn on the

in them is eliminated because they depend upon rolling

stationary differential spider or cross pin.

contact rather than sliding contacts. Ball bearings often

are referred to as having point contact between balls and

Such bearings usually are known as plain bearings and

raceways; in the same sense, roller bearings are said to

are used only for low speeds or light duty or both.

have line contact between rollers and races. These are

Probably the next simplest plain bearing, also of the

merely descriptive terms, however, because the elastic

sliding-surface type, is the bushing that is replaceable

deformation occurring under load results in substantial

when worn. A bushing is usually of bronze or similar

areas of contact in either type. The starting friction of ball

relatively soft material and is pressed into a hole and

and roller bearings is but slightly greater than their

reamed to fit, forming a lining in which a journal rotates.

running friction, an important advantage in machinery

Plain bushings are suitable for radial loads only. Bronze

that is required to start frequently under load. They also

bushings formerly were used to a considerable extent in

can sustain high overloads for short periods without

automotive power transmission systems but have been

failure. Ordinarily, a ball or roller bearing does not fail

superseded by antifriction bearings

suddenly, but gives warning by a gradual decrease in

smoothness of running; whereas, the plain bearing is

subject to an accelerated type of failure that often results

in

TA233656

19-7

|

||

|

||