| Tweet |

Custom Search

|

|

|

||

TM 9-8000

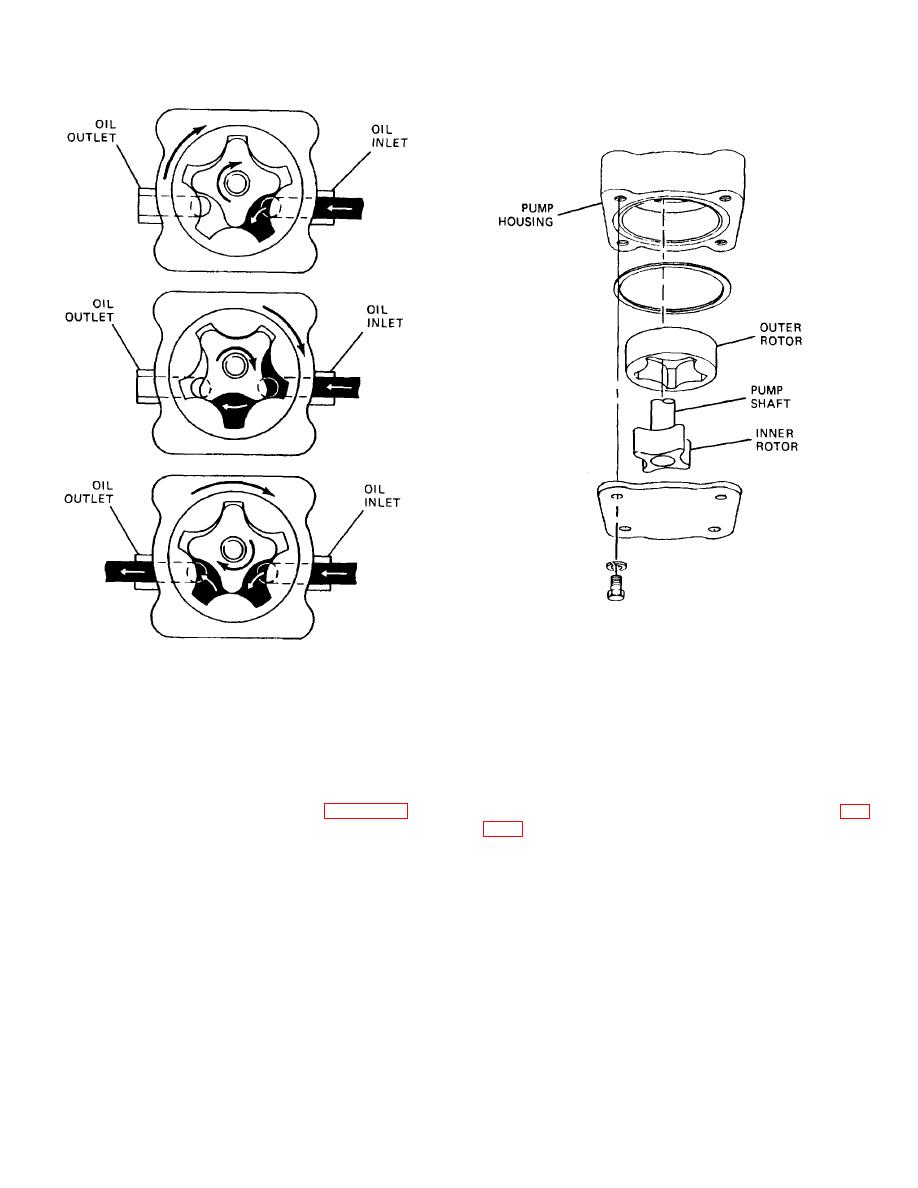

Figure 20-5. Rotary Pumps.

As the two rotors turn, the openings between them are

wedging action of the oil as it is forced toward the outlet

filled with oil. This oil then is forced out from between the

port by the vane.

rotors as the inner-rotor lobes enter the openings in the

outer lobes. This action is much like that in the gear-type

20-7.

Internal-External Gear Type. The internal-

pump.

external gear pump is composed of a large internal gear,

driven by an external gear offset from center. The space

between the two gears is occupied by a filler block (fig.

vane type. An integral steel rotor and shaft, one end

supported in the pump flange and the other end in the

drives, the larger gear. As the gears disengage and

cover, revolves in the body, the bore of which is eccentric

come in contact with the filler block, a differential in

to the rotor. Two sliding vanes are placed 180 degrees

pressure is developed, causing oil to enter the pump. It

apart in slots in the rotor and are pressed against the

then is transported past the filler block in the teeth of both

body bore by springs in the slots. When the shaft is

gears. Because the gear teeth begin to mesh again and

rotated, the vanes pick up oil at the inlet port and carry it

more oil is carried by the gears, pressure rises in the

around the body to the outlet side, where the oil is

outlet chamber and exits through the outlet port.

discharged. Pressure is produced by the

TA233670

20-4

|

||

|

||