| Tweet |

Custom Search

|

|

|

||

TM 9-8000

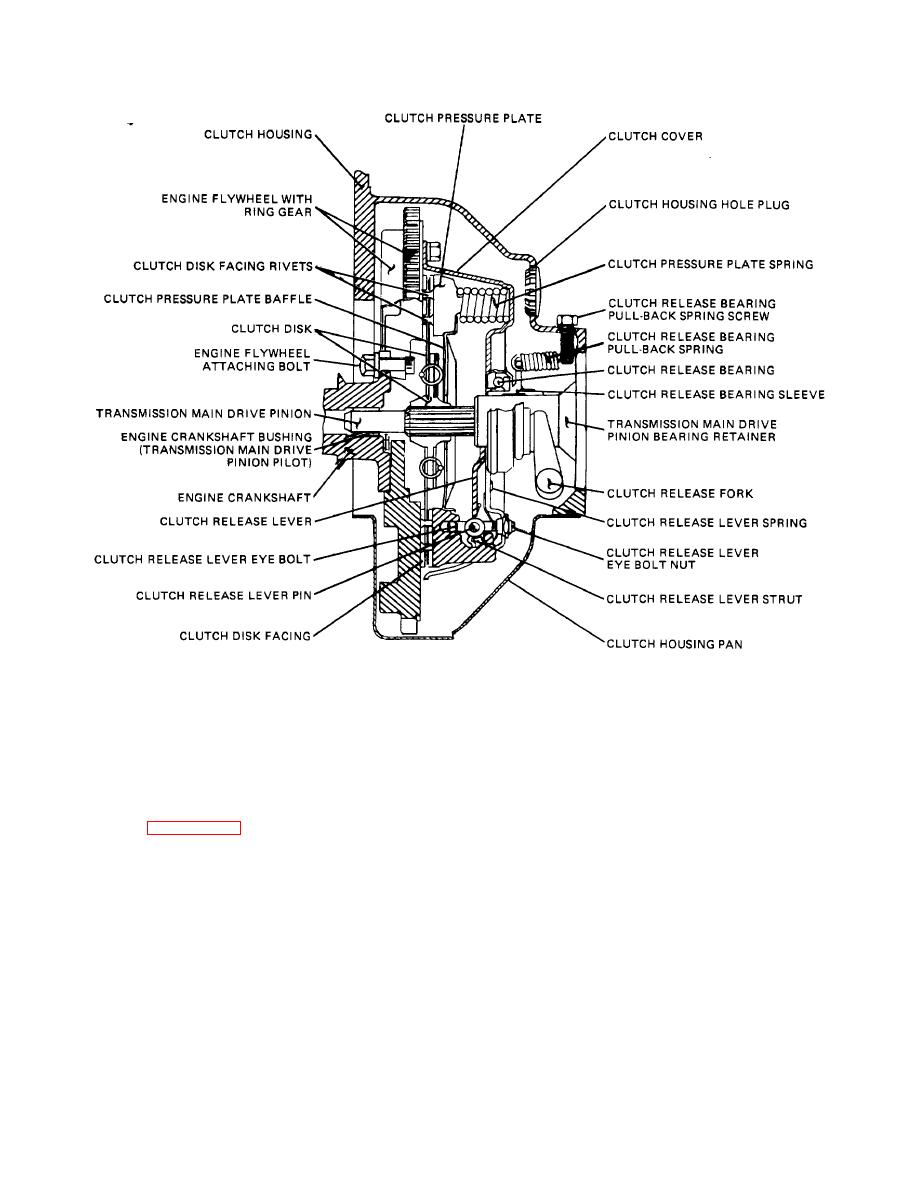

Figure 21-10. Simple Dry Plate Clutch.

causes the Inner section to move out, and the movement

forward, holding all the disks together firmly. This causes

of the outer rim forces the pressure plate against the

the clutch spider to revolve and turn the clutch shaft to

clutch disk, thus engaging the clutch.

which it Is keyed. In multiple-disk clutches, the facings

usually are attached to the driving disks. This reduces

d. Multlple-Dlsk Clutch. Typical multiple-disk clutches

the weight of the driven disks and, consequently, their

tendency to continue spinning after the clutch is released.

are shown In figures 21-11 and 21-12. Disks ranging In

Because of the considerable number of disks Involved,

numbers from 2 to 10 (and often as many as 11 driving

the pressure plate has to move farther to separate the

and 10 driven disks for heavy vehicles) are used. The

disks completely than It does In clutches having fewer

driving disks have lugs similar to gear teeth around their

driving and driven members. There Is, therefore, less

outside edges. These mesh with Internal splines In the

mechanical advantage on the clutch pedal and a greater

clutch case, which Is bolted to and rotates with the

foot pressure Is required to depress it.

flywheel. The driven disks are carried on parallel pins,

which are solidly set In the clutch spider. This

e. In a wet-type clutch, the disks and the entire internal

construction permits movement of all the disks and the

assembly run In an oil bath. The operation of this type of

pressure plate in order to provide clearance between

clutch Is similar to that of the dry type, except that the

them. When the clutch is engaged, the spring moves the

friction surfaces are

pressure plate

TA233681

21-9

|

||

|

||