| Tweet |

Custom Search

|

|

|

||

TM 9-8000

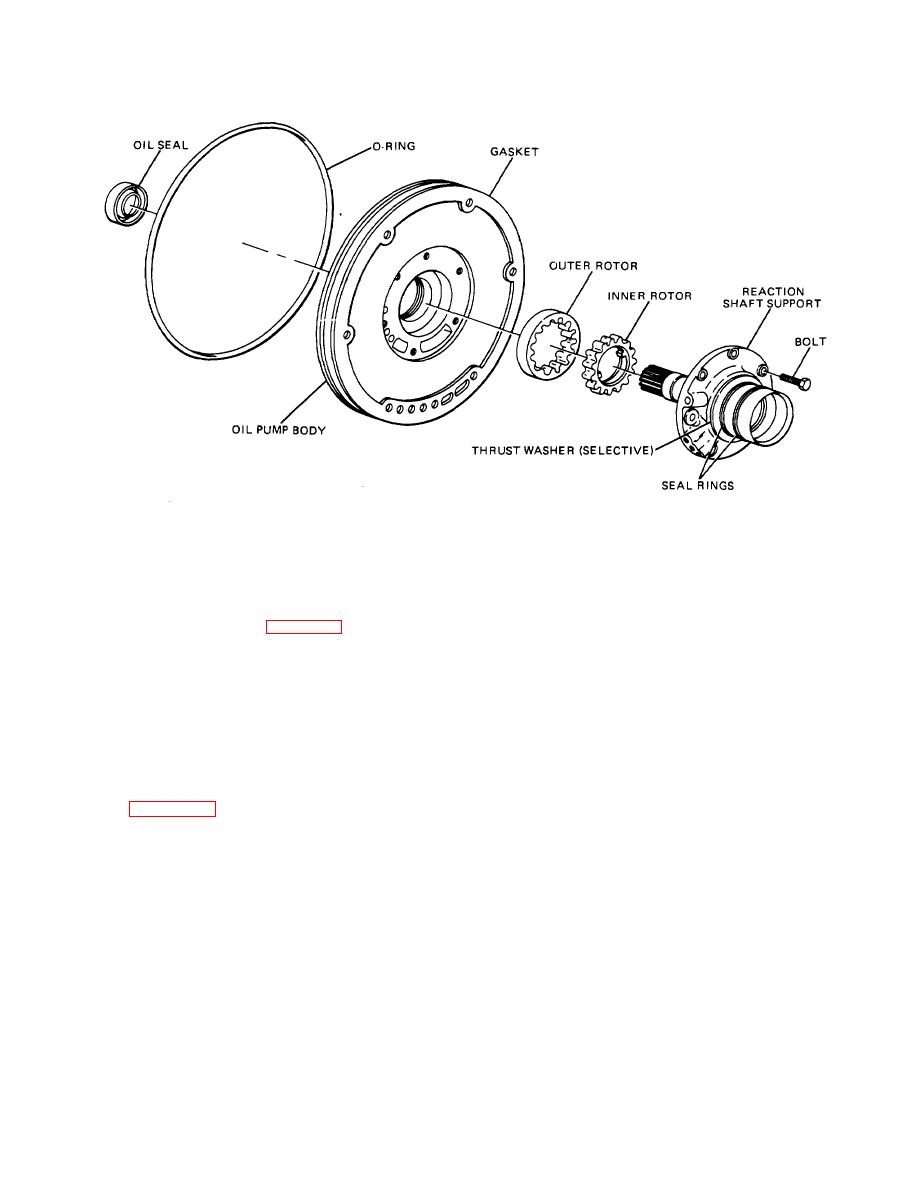

Figure 23-11. Typical Transmission Hydraulic Pump.

pressure signal attempts to move the spool against

20-5) or an internal-external gear-type pump (para 20-7).

spring pressure.

It usually is located in the front of the transmission case

and is keyed to the torque converter hub so that it is

(3) As pump pressure overcomes the

driven by the engine.

b. Oil Sump and Filter (Fig. 23-10). The oil

spring pressure, the spool is pushed to the left,

uncovering the pump suction feedback port. Pump

sump usually is in the form of a sheet metal pan that

pressure then is bled off through this port, causing a line

attaches to the bottom of the transmission case. The

pressure drop.

pump draws oil from the sump through a strainer. The

strainer usually is made of paper or metal.

(4) The line pressure drop allows the

c. Regulator Valve. The regulator valve controls

spring to close the bleed port, which, in turn, allows

pump pressure to build again. From then on the

the pressure of the hydraulic pump so that the hydraulic

regulation of line pressure is a constant cycle between

system of the transmission receives a constant working

pump and spring pressure operating the spool valve.

pressure. The pressure supply received by the hydraulic

system is called line pressure. The basic regulator valve

The valve described above is a balance-type spool valve.

is shown in figure 23-10.

Balance-type spool valves are very common in the

transmission's hydraulic system.

(1) Pump pressure is fed to the hydraulic

system through the spool valve. The spool is held to the

d. Modulation of the Regulator Valve (Fig.

right by a calibrated spring. In this position, the spool

23,10). After the pump pressure passes through the

closes the port that allows pump pressure to be fed back

to the pump suction line.

regulator valve, it becomes regulated line pressure. In

(2) After the pump pressure leaves the

operation, however, automatic transmissions need

spool valve, a portion of it is fed back to the end of the

more than one set line pressure. To accomplish this,

spool valve, opposite to the spring. This pump

additional signals are fed to the regulator to modulate the

line pressure for specific purposes. The following

TA233708

23-13

|

||

|

||