| Tweet |

Custom Search

|

|

|

||

TM 9-8000

immediately to the opposite wheel via the cone clutches.

b. The gear ratio of the bevel gear final drive is

(4) Slippage of One Wheel in Reverse.

found by dividing the number of teeth on the bevel drive

Because the spiral grooves that are cut into the cone

gear by the number of teeth on the pinion. For a worm

clutches are directional, the cone clutch no-spin

gear, it is found by dividing the number of teeth on the

differential will not work in reverse because the cone

worm gear by the number of threads on the worm. In the

clutches will unscrew themselves from the case, causing

case of chain drives, the sprockets are considered

the no-spin feature to be inoperative.

gears, and the number of teeth on the driven sprocket is

divided by the number of teeth on the driving sprocket.

Section III. 29-8.

Overview.

29-9.

Gear Drives.

a. A final drive is that part of a power transmission

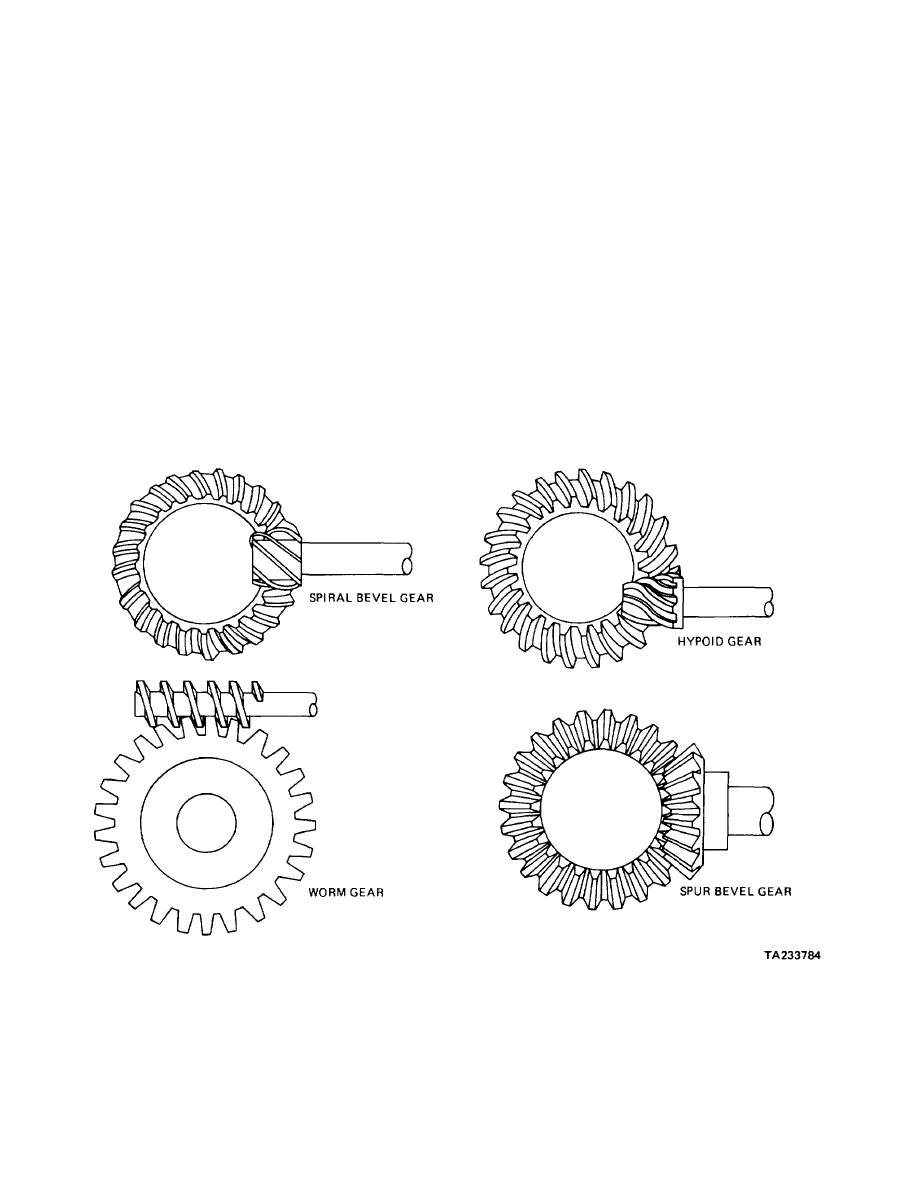

a. General (Fig. 298). All the final drives in general

system between the propeller shaft and the differential.

use are geared. The most common of these consists of

Its function is to change the direction of the power

a pair of bevel gears; that is, a drive pinion connected to

transmitted by the propeller shaft through 90 degrees to

the propeller shaft and a bevel drive gear attached to the

the driving axles. At the same time, it provides a fixed

differential case on the driving axle. These bevel gears

reduction between the speed of the propeller shaft and

may be spur, spiral-bevel, or hypoid. Spur gears have

the axle driving the wheels. In passenger cars, this

straight teeth, while spiral-bevel and hypoid

speed reduction varies from about 3:1 to 5:1. In trucks, it

varies from about 5:1 to 11:1.

Figure 29-8. Gear Drive Configurations.

29-8

|

||

|

||