| Tweet |

Custom Search

|

|

|

||

TM 9-8000

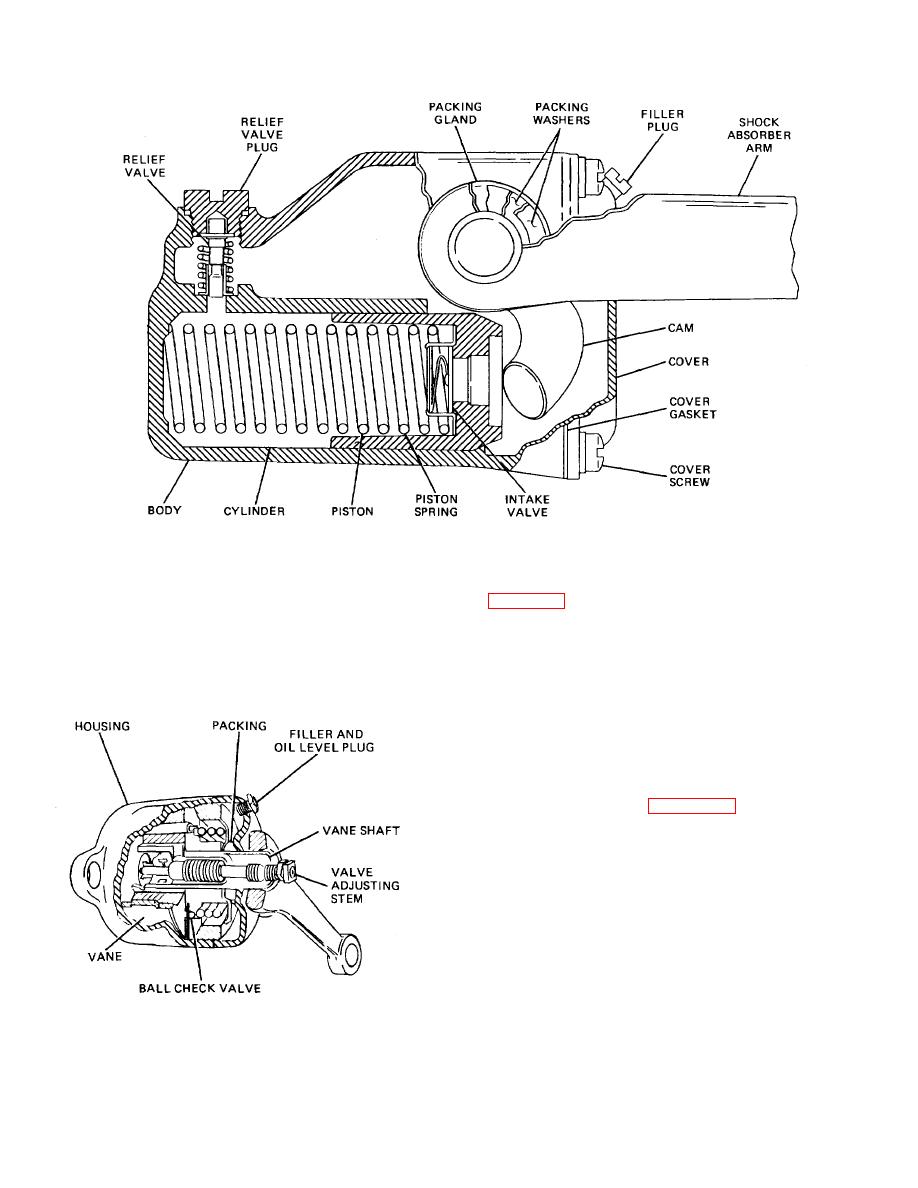

Figure 30-21. Single-Acting Cam-Operated Shock Absorber.

valves in the stationary partitions. On the rebound

c. Direct Acting. The direct-acting shock absorber

stroke, the vanes develop a pressure on the opposite

side, closing the check valves. Because oil cannot flow

through tire check valves, it is forced through the needle

special shock absorber oil, divided into an upper and

valve in the center of the shaft, thereby producing a

lower chamber by a double-acting piston. The shock

resistance to motion of the arm. The vane-type shock

absorber is mounted by studs and rubber bushings

absorber is not used widely, primarily because of the

inserted through the eye on each end so that it is acted

high cost and poor reliability resulting from the difficulty in

directly upon by spring action. The piston push rod,

sealing this type.

therefore, is forced up and down within the inner cylinder.

A reservoir that contains an ample supply of oil

surrounds the inner cylinder and is joined to it by a

reservoir check valve. When the vehicle spring is

compressed, the piston is forced down, and some of the

oil below the piston is forced through compression valves

(only one is illustrated in figure 30-23) inside the piston to

the upper chamber. These valves operate only on the

downstroke. Because the push rod moves into the

cylinder on the downstroke, some of the oil in the lower

chamber is forced through the check valve at the bottom

of the cylinder into the reservoir.

When the vehicle spring rebounds, the piston is moved

up, and oil from the upper chamber is forced into the

lower chamber through spring-loaded rebound valves

inside the piston. These valves control the rebound of

the

vehicle

spring.

Figure 30-22. Vane-Type Shock Absorbers.

TA233812

30-15

|

||

|

||