TM 5-2815-241-34&P

VALVE AND INJECTOR ADJUSTMENTS - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

NOTE

With accessory drive pulley timing mark at A or 1-6 VS, number three injector has been

adjusted. Valves in number five cylinder now must be adjusted.

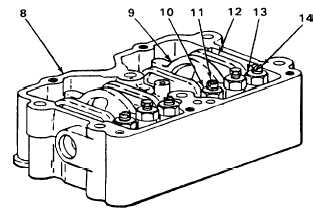

15. Rocker arm

housing (8)

Intake rocker arm

(9), locknut (10), and

adjusting screw (11)

a.

Using 3/8-inch drive ST-669 adapter

set, and 1/4-inch drive 7/16-inch

socket, loosen locknut and unscrew

adjusting screw.

b.

Using thickness gage, put in between

rocker arm and crosshead.

Clearance should be 0.011 inch

(0.28 mm).

c.

Using 3/8-inch drive ST-669 adapter set

and 0 to 150 ft lb (0 to 210 N•m) torque

wrench, torque to 25 to 35 ft lb (35 to

49 N•m).

16.

Exhaust rocker arm

Perform same adjustment procedures de-

(12), locknut (13),

scribed in step 15.

and adjusting

Clearance should be 0.023 Inch

screw (14)

(0.58 mm).

NOTE

Repeat steps 5 thru 16 as per Injector and Valve Set Position table below.

INJECTOR AND VALVE SET POSITION

ADJUST

CYLINDER

ROTATION

PULLEY

DIRECTION

POSITION

INJECTOR

V A L V E

Start

1-6 “ V S ”

3

5

Advance t o

2-5 “ V S ”

6

3

Advance to

3-4 “ V S ”

2

6

Advance t o

1-6 “ V S ”

4

2

Advance t o

2-5 “ V S ”

1

4

Advance t o

3-4 “ V S ”

5

1

NOTE: Two complete revolutions of the pulley are required

to adjust all injectors and valves.

T A 2 4 2 4 0 4

2-111

|

|