T M 9 - 2 8 1 5 - 2 0 2 - 3 4

NOTE

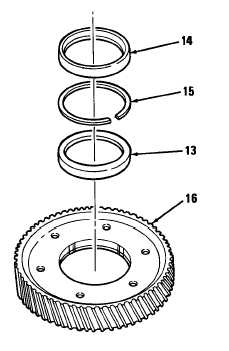

Do not remove bearing cups (13

and 14) and spacer ring (15) unless

loose or damaged.

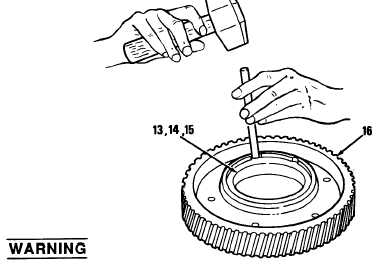

(5) Tap bearing cups (13 and 14) and

outer spacer ring (15) out of idler gear

(16) using a brass rod alternating

around four notches on shoulder of

gear.

c. Cleaning/Inspection

d.

Compressed air used for cleaning purposes will not exceed 30 PSI. Use

only with effective chip guarding and personal protective equipment

( g o g g l e s / s h i e l d , g l o v e s , e t c ) .

(1) Clean all parts using fuel oil. Dry with compressed air.

(2) Inspect all parts and replace if worn or damaged.

NOTE

Replace bearing cones, cups, and spacer rings as

(3) Coat all parts with engine oil.

Assembly

(1)

(2)

(3)

Place idler gear (16) shoulder down

on bed of arbor press.

Place inner bearing cup (13),

numbered side up, into bore of gear.

Press bearing cup against shoulder of

gear (16) using a steel plate under

ram of arbor press.

Lay outer spacer ring (15) on face of

a set.

bearing cup (13).

4 - 8 9

|

|