TM9-2815-202-34

4-41. BLOWER REPAIR (Cont)

(31)

(32)

(33)

(34)

(35)

(36)

(37)

(38)

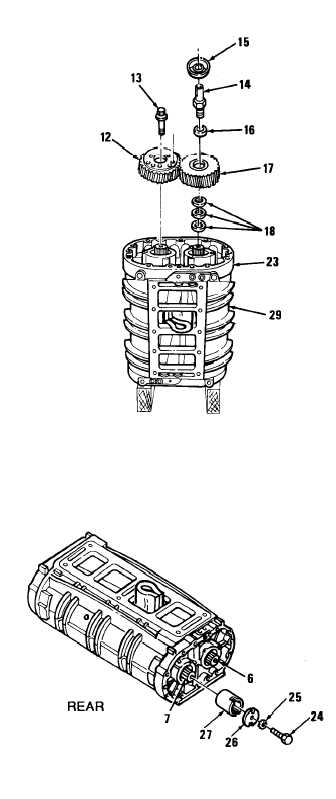

Rotate rotors (6 and 7) to bring flat in

spline on shafts in alinement and

facing left.

Install original number and thickness

of shims (18) on shafts of rotors (6

and 7) that were removed at

disassembly.

Lubricate serrations of shafts of rotors

(6 and 7) with engine oil.

Place teeth of rotor gears (12 and 17)

so missing teeth on inside of gears

are alined and facing same direction

as missing teeth on shafts of rotors (6

and 7).

Using a soft-headed hammer, drive

gear (12) on shaft of rotor (7) and

gear (17) on shaft of rotor (6).

Install bolt (13) into end in shaft of

rotor (7). Install spacer (16), shaft (14)

and deflector (15) in shaft of rotor (6).

Place folded rag between rotors to

prevent gears (12 and 17) from

turning. Torque bolt and shaft to

100-110 Ib-ft (136-150 N-m).

Reverse blower assembly. Install

spacer (27), disc (26), key washer

(25) and bolt (24) to rotor (7). Aline

tang on key washer with groove in

disc. Torque bolt to 55-65 Ib-ft

(75-88 N-m). Bend one tang of key

washer into groove in disc and two

tangs against side of bolt head.

Remove rag from rotors.

Install four 5/16-18x1 7/8-inch bolts

with flat washers through holes in

each end plate (top and bottom) to

blower housing. Torque bolts to

13-17 Ib-ft (18-23 N-m) (bolts are

temporarily securing blower housing

to end plates to determine clearance

between rotors and end plates).

4-244

|

|