TM9-2815-202-34

(43)

(44)

(45)

(46)

(47)

Check clearances at points (D) and (E). Insert feeler gages between lobes of rotors (6 and 7)

and blower housing (29). Measure clearance for each lobe at both inlet and outlet side (total

of twelve). Minimum clearance at (D) is 0.015 inch and at (E) is 0.004 inch.

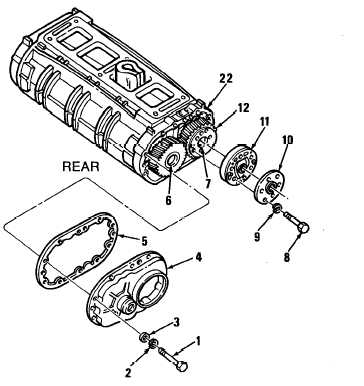

Place blower assembly on end on two wood blocks with gear end up. Place blower drive

coupling (1 O) on gear (12) with groove inside coupling next to gear. Install coupling, retainer

(11 ), six bolts (8), and six Iockwashers (9) to gear(11 ). Insert folded rag between rotors (6

and 7). Torque bolts to 20-25 Ib-ft (27-34 N-m). Remove rag.

Using dial indicator, measure cam spline runout. Maximum runout must not exceed 0.020

inch total indicator reading.

Remove four bolts and four flat washers holding each end plate to blower housing (installed

to check blower clearances).

Position gasket (5) on blower rear end plate cover (4) and loosely secure cover and gasket

to rear end plate (22) with ten bolts (1), ten Iockwashers (2), and ten special washers (3).

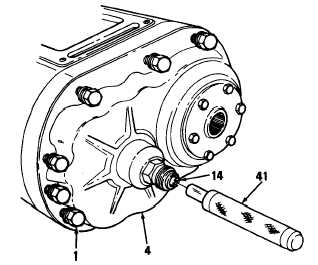

NOTE

Whenever installing a tachometer drive cover assembly or drive adaptor, maintain

proper alinement between cover and tachometer drive shaft. Correct alinement is when

no binding occurs between drive shaft and inside diameter of alinement tool when

rotating blower rotors.

(48) Using tachometer drive alinement set (41), aline cover (4) with tachometer drive shaft (14) by

.

.

selecting tool with best fit. Torque bolts (1) to 13-17 Ib-ft (1 8-23 N-m).

END OF TASK

FOLLOW-ON MAINTENANCE

Para Description

4-12 Install fuel pump

4-17 Install governor cover and throttle

control rod

4-18 Install governor and blower assembly

4-247

|

|