TM9-2815-202-34

8-14. CYLINDER COMPRESSION TEST (Cent)

NO FUEL

9.

h.

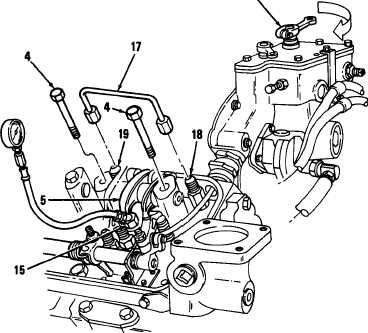

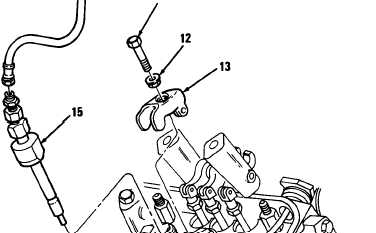

Position rocker arms (5) over pressure

gage and adapter (15) and exhaust valves.

Install two rocker arm shaft bolts (4) and

torque to 90-100 Ib-ft (122-136 N-m).

l

l

l

NOTE

Do not crank engine using starter

motor to obtain compression

pressure. Engine must be running

to obtain accurate reading.

Variation in compression pressures

between cylinders must not exceed

25 PSI (172 kPa) at 600 RPM.

Use spare fuel line to fabricate a

jumper connection between fuel

inlet and return manifold

connectors. Fuel line cannot be

reinstalled on engine.

Install spare fuel line (17) between inlet

manifold (18) and return manifold (19).

l

l

WARNING

Avoid contact with hot

manifolds, pulleys, and

other moving parts to avoid

personal Injury.

Wear proper ear protection

when running engine. Noise

volume of engine can cause

hearing loss or injury.

Protective turbocharger air

inlet shield must be

Installed prior to doing

maintenance when engine Is

running and air Inlet has

been removed. Contact with

rotating blades will cause

injury to personnel.

CAUTION

Run engine in clean area when air

intake ducting is removed. Dirt, dust,

and particles in unfiltered air can

enter engine and damage parts or

cause mechanical failure.

.

,

1

POSITION

Yo

/ ‘6

11

i. Start engine and run at 600 RPM. Record

pressure shown on cylinder tester gage.

8-36

|

|