ARMY TM 9-2815-260-24

AIR FORCE TO 38G1-126-2

MARINE CORPS TM 09244A/09245A-24

5-19

(5)

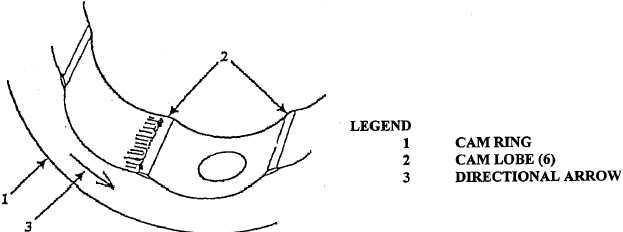

Inspect cam ring (1, Figure 5-18). Carefully inspect cam lobes and edges of all flat surfaces. If

there is evidence of spalling or flaking out, replace with a new cam.

NOTE

Only working portions of lobes on inside diameter are ground, so any tool

marks between lobes should not be considered as damage. The mottled

appearance of cam is from heat treatment rather than from operation.

FIGURE 5-18. CAM RING.

(6)

Examine the Hydraulic Head Assembly. Refer to Figure 5-19.

(a)

Examine the metering valve bore and the threaded holes for damage.

(b)

Examine the rotor bore for wear band in line with the charging ports and/or the discharge

ports which could indicate that dirty fuel was used.

(c)

Inspect the discharge fittings for damage to the area where the injection lines seat or to

the threads.

(d)

Check the threaded hydraulic head plugs to ensure they are tight.

(e)

Replace the Hydraulic Head Assembly if found defective.

|

|