| Tweet |

Custom Search

|

|

|

||

AIR INLET AND EXHAUST SYSTEM

TESTING AND ADJUSTING

3.

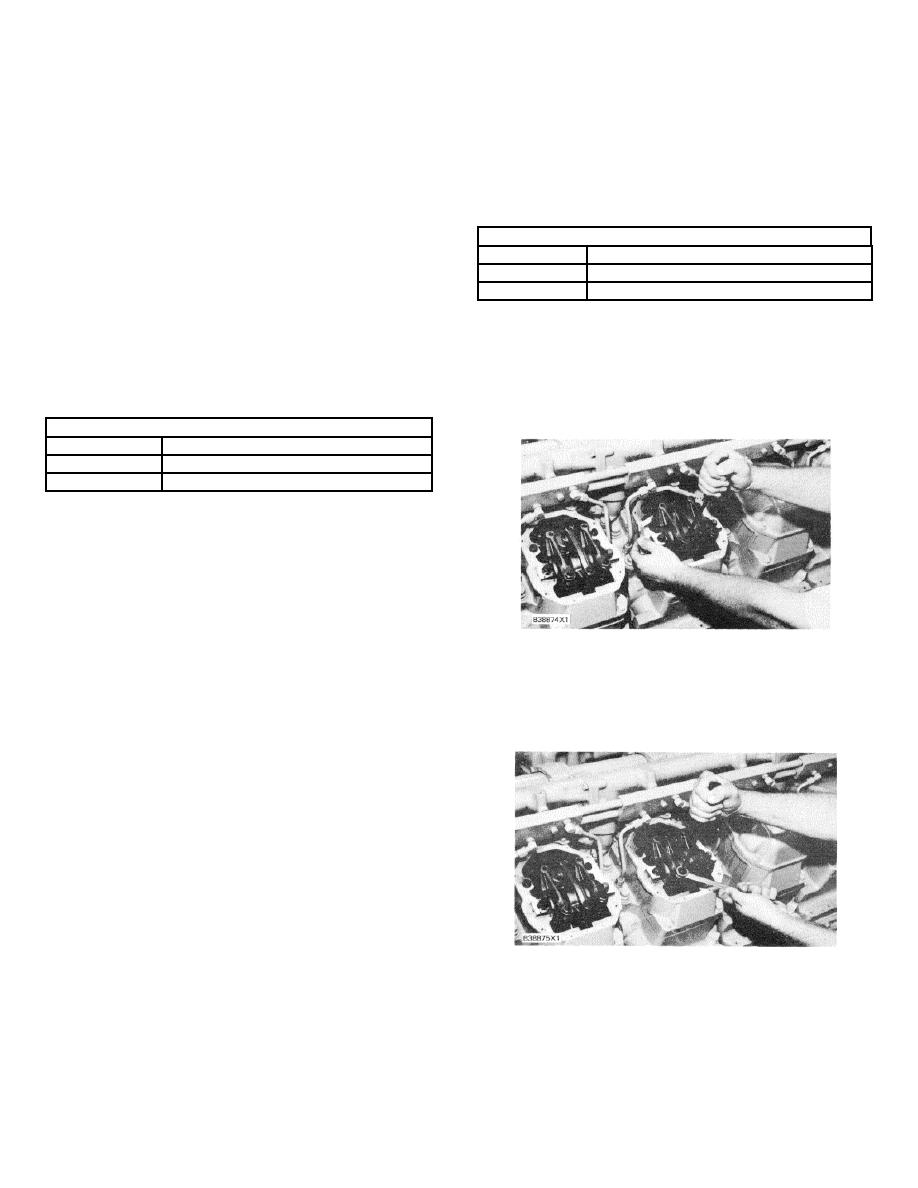

Loosen the locknut for the push rod adjustment

VALVE CLEARANCE

screw. If there is not enough clearance for feeler

gauge between rocker arm and bridge contact

Valve clearance (lash) is measured between the

surface,

turn

the

adjustment

screw

rocker arm and the bridge for the valves. All clearance

counterclockwise to increase the valve

measurements and adjustments must be made with the

clearance.

engine stopped, and with the valves FULLY CLOSED.

VALVE CLEARANCE SETTING: ENGINE STOPPED

Valve Clearance Check

VALVES

GUAGE DIMENSION

When the valve clearance is checked,

Intake

0.28 mm (.015 in.)

adjustment is NOT NECESSARY if the measurement is

0.76 mm (.030 in.)

in the range given in the chart for VALVE CLEARANCE

CHECK: ENGINE STOPPED.

However, it is the

4.

Put a feeler gauge of the correct dimension

recommendation of Caterpillar that the valve clearance

between the rocker arm and bridge contact

setting is to be made at the initial (first) 1000 service

surface. Turn the adjustment screw clockwise

hours of operation, and every 3000 service hours

until the valve clearance is set to the

thereafter.

specifications in the chart VALVE CLEARANCE

SETTING: ENGINE STOPPED.

VALVE CLEARANCE: ENGINE STOPPED

VALVES

ACCEPTABLE CLEARANCE RANGE

Intake

0.30 to 0.46 mm (.012 to .018 in.)

0.68 to 0.84 mm (.027 to .033 in.)

If the measurement is not within this range, or if

the service meter indication is at the specified interval,

adjustment is necessary.

See the subject VALVE

CLEARANCE ADJUSTMENT.

Valve Clearance Adjustment

NOTICE

VALVE CLEARANCE ADJUSTMENT

Due to normal changes (break-in effects) of new or

rebuilt engines, the recommended first interval for

5.

After each adjustment, tighten the nut for the

valve clearance setting is at 1000 service hours of

adjustment screw to a torque of 70 + 15 N-m (50

engine operation.

+ 11 lb. ft.) and check the adjustment again.

Use the procedure that follows for adjustment of

the valves:

1.

Put No. 1 piston at top center (TC) position.

Make reference to FINDING TOP CENTER

POSITION FOR NO. 1 PISTON.

2.

With No. 1 piston at top center position of the

correct stroke, adjustment can be made to the

valves as shown in the chart CRANKSHAFT

POSITIONS FOR FUEL TIMING AND VALVE

CLEARANCE SETTING.

NOTE: Before any actual adjustments are made, tap (hit

TIGHTEN

ADJUSTMENT

SCREW

LOCKNUT

lightly) each rocker arm (at top of adjustment screw) with

a soft hammer to be sure that the lifter roller is seated

against the camshaft base circle.

137

|

||

|

||