2-4. MALFUNCTION, TEST OR INSPECTION, AND

(continued)

TM 9-2520-272-34&P

CORRECTIVE ACTION PROCEDURES

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3.

VEHICLE DOES NOT MOVE FORWARD IN ANY SHIFT LEVER FORWARD POSITION,

NORMAL OPERATION IN ALL OTHER SHIFT LEVER POSITIONS (Continued)

Step 3.

Check vehicle operation.

a If operation is normal return vehicle to service.

b. If original symptom is still present, transmission is defective beyond the

Ievel of Direct Support Maintenance. Separate transmission from power

pack in accordance with TM 9-1450-300-34 or TM 9-2350-277-34 and send

to General Support.

GENERAL SUPPORT. The following maintenance action is indicated:

Repair Area:

A problem in the range clutch area of the transmission is indicated, with the

probability that the fourth-reverse (C-2) clutch and related components are

affected.

Repair Procedure Reference:

Refer to para.4-28 for fourth-reverse (C-2) clutch maintenance tasks.

4.

VEHICLE DOES NOT MOVE IN ANY SHIFT LEVER POSITION

PRELIMINARY TROUBLESHOOTING. Organizational maintenance determined:

• Shift tower circuit breaker tripped when vehicle harness

connector at transmission was connected to transmission, or,

• Circuit breaker operation, voltages at vehicle harness

connector at transmission, and main pressure were normal.

Step 1.

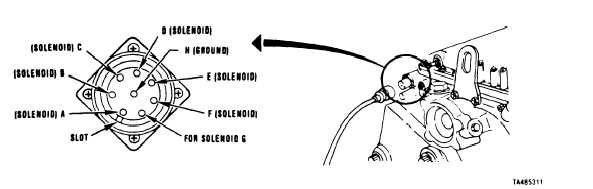

With master switch at OFF, disconnect vehicle harness connector at

transmission. Perform resistance checks to ground (Pin H) and

solenoid pins B, C and E (Reverse Range) and A and C (Forward

Range). Pin designations match actuating solenoids A, B, C and E.

Resistance reading must be 60-80 ohms.

Para. 2-4

2-7

|

|