TM9-2815-202-34

4-25. IDLER GEAR REPLACEMENT

This task covers:

a. Removal

b. Disassembly

c. Cleaning/Inspection

d. Assembly

e. Installation

INITIAL SETUP

MODELS

All

TOOLS/SPECIAL TOOLS

General mechanics tool kit (App B, Item 96)

Bearing test fixture (App D, Item 2)

Magnetic base dial indicator

(App B, Item 45)

Spring scale (App B, Item 24)

Torque wrench (App B, Item 101)

MANDATORY REPLACEMENT (PARTS)

6 Bolts (App F, Item 4)

EXPENDABLE/DURABLE SUPPLIES

Fuel oil (App C, Item 21)

Engine oil (App C, Item 16)

Lintless cord (App C, Item 26)

EQUIPMENT CONDITION

Para Description

4-24 Flywheel housing removed

NOTE

Before removing idler gear

assembly from engine, check idler

gear assembly for any wobble or

shake. Firmly grasp rim of gear with

both hands and rock it. If gear

wobbles or shakes, bearing is bad

and must be replaced.

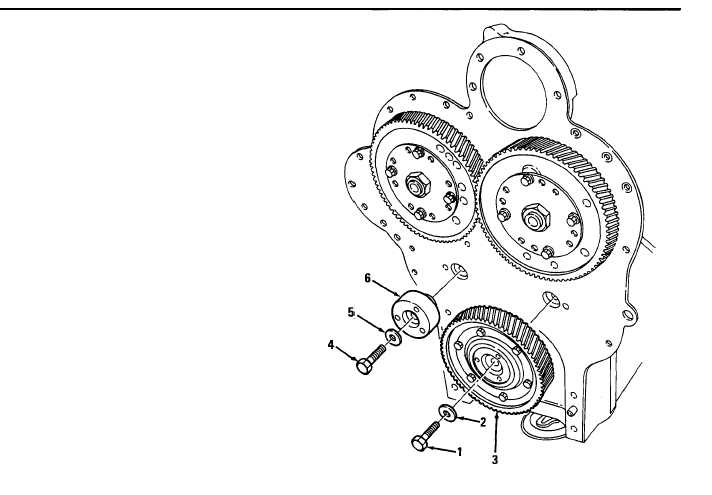

a. Removal

(1) Remove bolt (1) and flat washer (2)

securing idler gear assembly (3) to

cylinder block. Remove idler gear

assembly from engine block.

NOTE

Effective up to engine number

8VA-349267, a dummy hub was

installed opposite idler gear hub to

fit the original flywheel housing.

4 .

(2) Remove bolt (4) and flat washer (5)

securing dummy hub (6) to cylinder

block. Remove dummy hub (6) from

engine block.

Change 1

4-87

|

|