TM9-2815-202-34

4-31. OIL PRESSURE REGULATOR AND RELIEF VALVE REPLACEMENT (Cent)

b. Repair

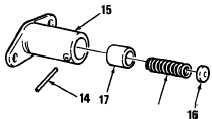

(1) Regulator Valve

WARNING

Firmly secure spring during removal. A spring loaded mechanism ejects

parts at high speed If released In

injury may result.

(a)

(b)

Clamp regulator assembly in a

vise with soft jaws. Compress

spring (13) and remove retaining

pin (14) from regulator body (15).

.Remove spring seat (16), spring

an uncontrolled manner. Personal

(13), and valve (17) from

regulator body (15).

WARNING

13

16

(2)

Compressed air used for cleaning purposes will not exceed 30 psi. Use

only with effective chip guarding- and personal protective equipment

(goggles/ shield, gloves, etc).

(c)

(d)

(e)

(f)

(9)

(h)

Clean all parts with fuel oil and dry with compressed air.

Inspect parts for wear and damage. Regulator valve must move freely in valve body.

Replace valve and valve body if parts are scored and cannot be cleaned with crocus

cloth.

Replace a pitted or fractured spring.

Assemble valve assembly by first applying engine oil to outer face of valve (17) and

slide it into regulator body (15), closed end first.

Install spring (13) and spring seat (16) into regulator body (15).

While compressing spring, install retaining pin

Relief Valve

WARNING

(14) above spring seat (16).

l

l

+

.

Firmly secure spring during removal. A spring loaded mechanism ejects

parts at high speed If released In an uncontrolled manner. Personal

injury may result.

(a) Clamp relief valve assembly in a vise with soft iaws. CornDress.@rms(18 and 19) and

l

. .

remove

retaining

pin

(20)

f~om relief valve body (21). “ “ - ‘ ‘

(b) Remove spring seat (22), springs (18 and 19), two inner spring seats (23), and valve

(24) from relief valve body (21 ).

e

4-122

|

|