TM9-2815-202-34

WARNING

Compressed air used for

cleaning purposes will not

exceed 30 psi. Use only with

effective chip guarding and

personai protective equipment

(goggies/ shieid, gioves, etc).

(c)

(d)

(e)

(f)

(9)

(h)

Ciean aii parts with fuei oii and

LL

dry with compressed air.

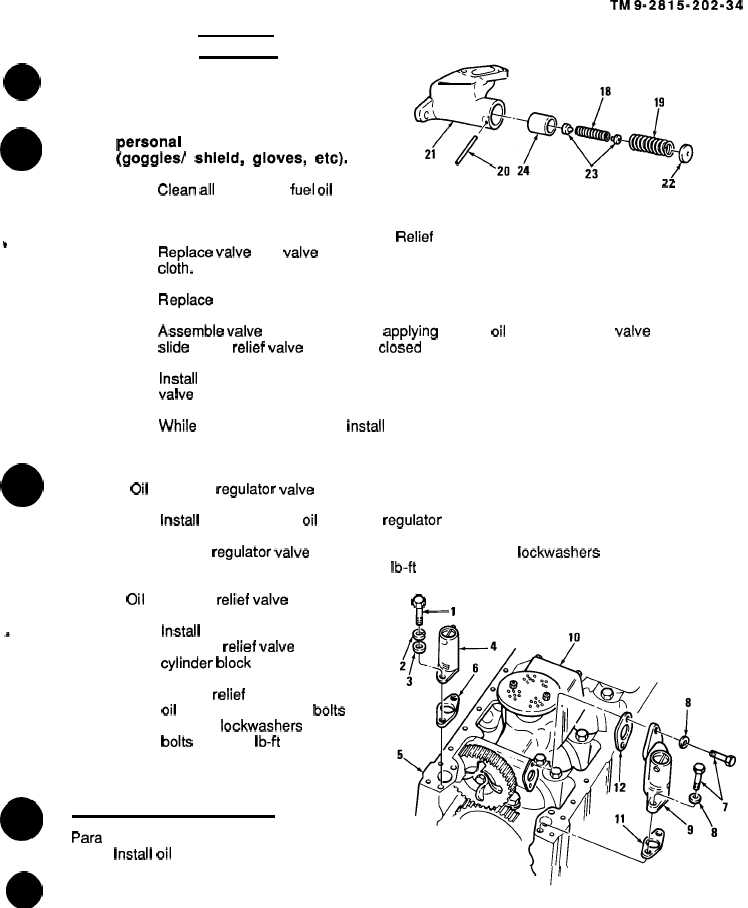

inspect parts for wear and damage. Reiief valve must move freely in valve body.

Repiace vaive and vaive body if parts are scored and cannot be cleaned with crocus

cioth.

Repiace pitted or fractured springs.

Assembie vaive assembly by first appiying engine oii to outer face of vaive (24) and

siide it into reiief vaive body (21), ciosed end first.

instaii two inner spring seats (23), springs (18 and 19), and spring seat (22) into relief

vaive body (21).

Whiie compressing springs, instaii retaining pin (20) above spring seat (22).

b

c. installation

(1) Oii

(a)

(b)

pressure reguiator vaive

instaii gasket (6) and oii pressure reguiator valve (4) to cylinder block (5).

Secure reguiator vaive to block with two bolts (1), two Iockwashers (2), and two flat

washers (3). Torque bolts to 30-35 Ib-ft (41-47 N-m).

(2) Oii pressure reiief vaive

@

*

(a)

(b)

instaii gaskets (11 and 12) and oil

pressure reiief vaive (9) to

cyiinder biock (5).

Secure reiief valve to block and

oii pump (10) with four boits (7)

and four iockwashers (8). Torque

boits to 30-35 ib-ft (41-47 N-m).

END OF TASK

FOLLOW-ON MAINTENANCE

Para Description

4-20 instaii oii pan

4 - 1 23

|

|