(c)

(d)

(e)

(f)

(9)

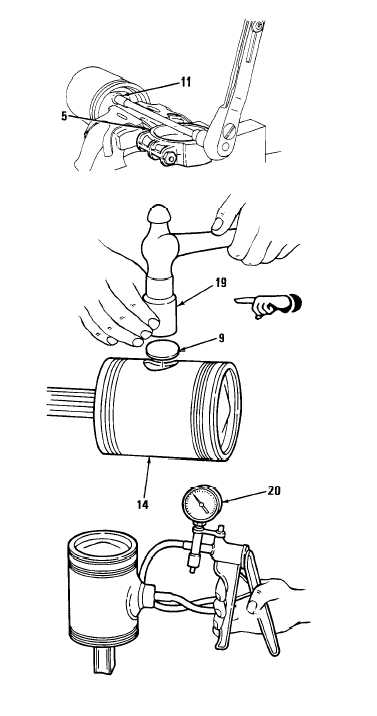

TM9-2815-202-34

Aline piston pin holes in skirt (14) and dome (15), then push skirt into position on dome.

Lubricate piston pin (12) and piston pin bushing (17) with engine oil and install piston

pin.

Install spacers (13) on piston pin bolts (11). Apply small amount of International

Compound No. 2, or equivalent, to bolt threads and bolt head contact surfaces.

Attach connecting rod (5) to piston pin (12) with two bolts (11) and two spacers (13).

Tighten bolts finger tight.

Clamp connecting rod (5) in soft-

jawed vise and torque piston pin

bolts (11 ) to 55-60 Ib-ft (75-81 N-

m). Do not exceed this torque.

CAUTION

Insure piston pin retainers do not

buckle during installation and seat

completely in counterbore with

width of land even around retainer

to seal properly.

(h) Insert piston pin retainer (9) in

position. Place crowned end of

piston pin installer (19) against

retainer. Strike tool just hard

enough to deflect retainer and to

seat it evenly in skirt (14), Install

second retainer in same manner.

(i) Check each retainer for proper

sealing with leak detector (20).

Place suction cup over retainer

and hand operate lever to pull a

vacuum of ten inches of Hg. on

gage. A drop in gage reading

indicates air leakage at retainer.

(2) Installation - Piston Rings

(a) Lubricate piston rings and piston

with engine oil before installing

rings.

Change 1

4 - 1 39

|

|