TM 9-2815-202-34

4-33. PISTON AND CONNECTING ROD MAINTENANCE (CROSS-HEAD) (Cont)

f. Fitting Piston Rings

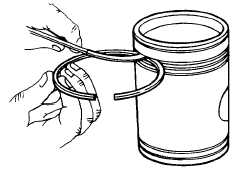

(1)

Insert top piston ring inside cylinder liner in normal area of ring travel. Use a piston skirt to

push ring down to insure ring is parallel with top of liner. Measure ring gap with feeler gage.

Refer to Table 4-3 for ring gap specifications. Repeat procedure for balance of compression

CAUTION

File or stone both ends of

compression ring from outer surface

to inner surface to prevent chipping

or peeling of chrome plating on ring.

Ends of ring must remain square,

and chamfer on outer edge must be

approximately 0.015 inch.

TABLE 4-3 PISTON RING SPECIFICATIONS

GAP (NO.2, AND 3)

CLEARANCE RING TO GROOVE:

TOP RING

NO.2

NO03

OIL CONTROL RINGS

GAP (TWO RINGS IN

LOWER GROOVE)

GAP (ONE RING IN

UPPER GROOVE)

CLEARANCE (TWO RINGS

IN LOWER GROOVE)

CLEARANCE (ONE RING

IN UPPER GROOVE)

MINIMUM

MAXIMUM

.0230 IN (.0286CM

.0380 IN. (.0965CM)

.0180 IN. (.0457CM)

.0430 IN. (.1092CM)

.C080 IN. (.0025CM)

.0050 IN (.0127CM)

,0100 IN. (.0254CM)

.0130 IN (.0330CM)

.0040 IN. (.0101CM)

.0070 IN. (.0177 CM)

.0080 IN (.0203CM)

I

.0230 IN. (.0584CM)

.0050 IN. (.0127CM)

.0140 IN. (.0356CM)

.)015 IN. (.0038CM)

.0055 IN. (0139CM)

.0010 IN. (.0025CM)

.0040 IN (.0101CM)

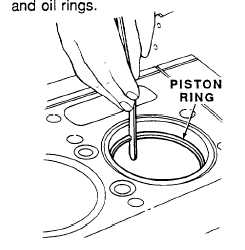

(3) Using feeler gage, measure ring side

clearance by inserting edge of ring in

appropriate groove of piston.

Refer to Table 4-3 for ring side

clearance specifications.

g. Assembly

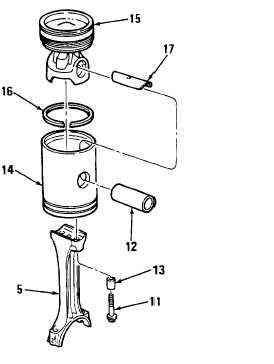

(1) Piston and Rod Assembly

(a) Install pin bushing (17) in piston

dome (15). It should slide into

piston dome without force.

NOTE

Soak seal rings in engine oil for 15

minutes prior to installation on

dome.

(b) Lubricate seal ring (16) and

install in groove on piston dome

(15).

Change 1

4-138

|

|