TM 9-2815-202-34

4-33. PISTON AND CONNECTING ROD MAINTENANCE (Cont)

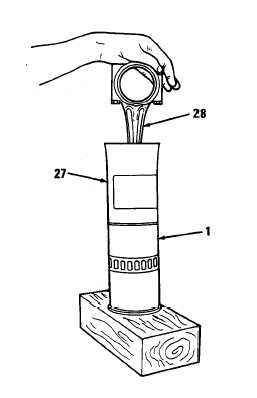

(3) Piston and Connecting Rod Assembly to Cylinder Liner

(a) Apply clean engine oil to piston, rings, and inside surface of piston ring compressor.

NOTE

Inspect ring compressor for nicks or burrs, especially at nontapered inside diameter

end. Nicks or burrs on inside diameter of compressor will result in damage to piston

rings.

(b)

(c)

(d)

(e)

Place piston ring compressor (27) on wood block, with tapered end of ring compressor

facing up.

Stagger piston ring gaps 90° apart on piston. Make sure ends of oil control ring expanders

are not overlapped.

Start top of piston straight into ring compressor (27). Then push piston down until it

contacts wood block.

Place liner (1) with flange end down on

wood block. Note position of

matchmark on liner.

NOTE

Numbers on side of connecting rod and cap identify rod with cap and indicate particular

cylinder in which they are used.

(f)

(g)

Place ring compressor (27) and piston

and connecting rod assembly (28) on

liner (1) with numbers on side of

connecting rod and cap aligned with

matchmark on liner.

Push piston and connecting rod

assembly (28) down into liner (1) until

piston is-free of ring compressor (27).

CAUTION

Do not force piston into liner.

Expanders apply considerable

force on oil rings; therefore,

extra care must be taken during

loading operation to prevent

ring breakage.

(h) Remove connecting rod cap and ring

compressor. Then push piston down

until compression rings pass cylinder

liner ports.

4-142

C h a n g e 1

|

|