TM 9-2815-202-34

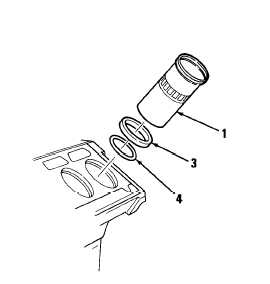

(3) Remove liner insert (3) and shims (4)

(if used) from counterbore in block.

(4) Tag liner, insert, and shims with

cylinder position number.

b. Cleaning

WARNING

Compressed air used for cleaning

purposes will not exceed 30 psi. -

Use only with effective chip

guarding and personal protective

equipment (goggles/ shield,

gloves, etc).

CAUTION

Always store liners in an upright

position until ready for use. Liners

left on their side can become

distorted.

Clean cylinder liner with fuel oil and dry with compressed air.

c. Inspection

(1)

(2)

(3)

(4)

Check outside of liners for cracks, scoring, and flange irregularities.

Discard cracked or excessively scored liners. Clean up slightly scored liners using cylinder

hone.

NOTE

Excessive liner to block clearance or block bore distortion will reduce heat transfer from

liner to block and to engine coolant. Stains or low pressure areas on outer surface of

liner indicate poor contact between liner and block bore.

Examine outside surface of liner for fretting. Remove metal particles from surface of liner with

a coarse flat stone.

Liner flange and liner insert must be smooth and flat on both top and bottom surfaces.

Replace liner if cracked at flange. Replace insert if there is evidence of brinelling.

4-145

|

|