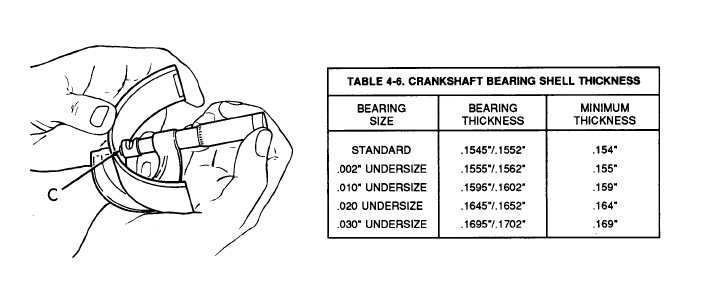

TABLE 4-6.

TM 9-2815-202-34

4-35. CRANKSHAFT MAINTENANCE (Cont.)

NOTE

Lower bearing shells, which carry the load, will normally show signs of distress before

upper bearing shells.

(9) Discard main

overlay.

bearings with signs of scoring, pitting, flaking, etching, overheating, or loss of

e. Measurements

(1) Using micrometer and ball attachment, measure thickness of bearing shells at point (C),

90 degrees from parting line. Replace all bearing shells if minimum thickness is less than

0.1540 inch. A standard bearing is 0.1545 to 0.1552 inch thick. Refer to Table 4-6 for

thickness of undersize bearings.

If clearance between any crankshaft journal and its bearing shells exceeds 0.0060

inch, all bearing shells must be discarded and replaced. Clearance for new parts is

0.0016 to 0.0050 inch.

(2) Check clearance between main bearings and crankshaft journals by using method (a) or (b)

below:

(a) With crankshaft removed, measure outside diameter of crankshaft main bearing journals

and inside diameter of main bearing shells in place with required bearing cap bolt

torque. When installed, bearing shells are 0.001 inch larger in diameter at parting line

than 90 degrees from parting line.

4-156

|

|