TM 9-2815-202-34

(b) With crankshaft installed, place plastic gage strip (19) between crankshaft journal (20)

and main bearing cap (7). Tighten main bearing bolts (21) to required torque. Remove

main bearing bolts and cap and measure width of plastic gage with measuring strip (22).

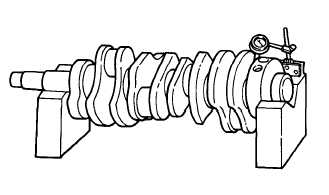

(3) Measure intermediate main bearing journal runout with dial indicator. Support crankshaft on

its front and rear journals on V-blocks or an inverted engine block with front and rear upper

bearing shells in place. When high spots of runout on adjacent journals are in opposite

directions, sum must not exceed 0.003 inch total indicator reading. When high spots of

runout on adjacent journals is in same direction, difference must not exceed 0.003 inch total

indicator reading. When high spots of runout on adjacent journals are at right angles to each

other, sum must not exceed 0.004 inch total indicator reading or 0.002 inch on each journal.

If runout limit is greater than 0.002 inch on No. 2 and No. 4 journals or greater than 0.004

inch on No. 3 journal, crankshaft must be replaced.

4-157

|

|