TM 9-2815-202-34

4-36. CYLINDER BLOCK MAINTENANCE (Cont)

(5) Using a bore gage, check main beating bore diameters with bearing caps in original position

and bolts torqued to 165-175 Ib-ft (224-238 N-m). Apply International Compound No. 2 to

bolt threads and bolt head contact area. Do not install main bearing cap stabilizers when

performing this check.

l

l

NOTE

Main bearing bore diameter is 4.812 to 4.813 inches. If bores do not meet these

limits, replace cylinder block.

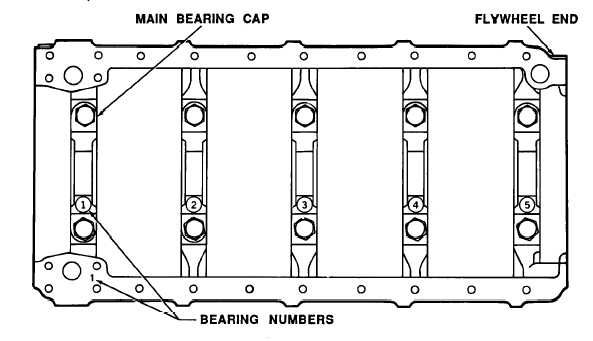

Main bearing caps are numbered to correspond with their respective positions in

cylinder block. No. 1 bearing cap is located at front of block and stamped on bottom

front oil pan rail.

(6) Check remainining cylinder block surfaces and threaded holes for damage. Check all mating

surfaces or mounting pads for flatness, nicks, and burrs. Clean up damaged threads in

tapped holes with a tap or install helical thread inserts if necessary.

If cylinder block is not to be used immediately, spray machined surfaces with engine

oil. If cylinder block is to be stored for an extended period of time, spray or dip block in

polar-type rust-preventive compound. Castings free of oil will rust when exposed to

atmosphere.

d. Assembly

NOTE

Apply pipe sealant to all plugs and fittings. Install cup plugs 0.090 to 0.140 inch below

surface unless otherwise noted.

4-170

|

|