TM 9-2815-202-34

4-36 CYLINDER BLOCK MAINTENANCE

e. Pressure Check

(1)

(2)

(3)

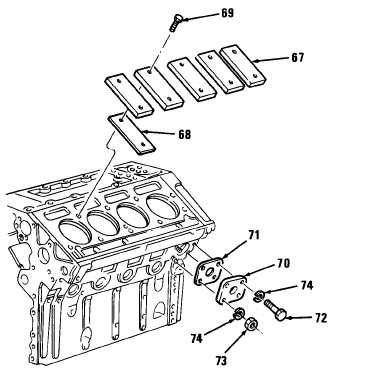

With all cylinder block plugs in place,

install ten blocking plates (67) and ten

gaskets (68), found in cylinder head

pressure testing kit, over water outlet

holes. Secure plates to top of cylinder

block with twenty 5/8-11 x 2 inch bolts

(69).

Install fabricated water outlet plate

(70) and rubber gasket (71). Secure

with two bolts (72), two nuts (73), and

four Iockwashers (74).

Attach an air line connection at plate

(70). Immerse block in a tank of water

heated to 180 to 200 oF (82-93 oC) for

twenty minutes.

(Cont.)

Never work on air system components without first gradually relieving air

pressure. Sudden release of air pressure can throw debris resulting in

serious personal injury.

(4) Apply 40 psi (276 kPa) air pressure to water jacket and observe water in tank for bubbles

which indicate a crack or leak in block. Replace block if cracked.

Compressed air used for cleaning purposes will not exceed 30 psi. Use

only with effective chip guarding and personal protective equipment

(goggles/shield, gloves, etc).

(5) After competing pressure test, remove block from water tank. Remove ten blocking plates

(67), ten rubber gaskets (68), twenty bolts (69), oil cooler plate (70), gasket (71), two bolts

(72), two nuts (73), and four Iockwashers (74). Dry block with compressed air.

END OF TASK

FOLLOW-ON MAINTENANCE

Para Description

3 - 6 Install oil cooler

4-18 Install blower

4-30 Install front and rear end plates

4-33 Install cylinder kits

4-35 Install crankshaft

4-174

|

|