TM 9-2815-202-34

4-37. TURBOCHARGER REPAIR (Cont)

d. Assembly

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

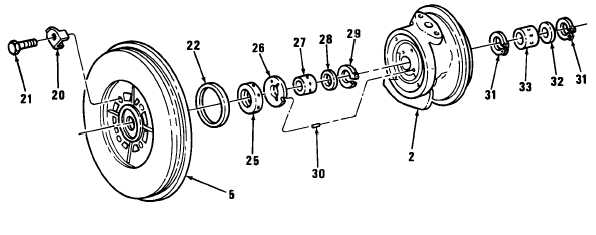

Lubricate bearings (27 and 33) with engine oil.

Install inner retaining ring (31 ), bearing (33), bearing washer (32), and outer retaining ring

(31) in turbine end of center housing (2).

Install retaining ring (29), bearing washer (28), and bearing (27) in compressor end of center

housing (2).

If removed, install two pins (30) in compressor end of center housing (2). Pins must extend

0.075 to 0.085 inch above surface.

Install thrust washer (26) with hole and cutout in thrust washer in alinement with pins (30).

Install thrust washer with smooth side against center housing.

Lubricate thrust collar (25) and thrust washer (26) with engine oil. With center housing

assembly (2) laying flat on bench, compressor end up, place thrust collar snugly against

thrust washer.

Install seal ring (22) in groove at compressor end of center housing (2).

Aline oil feed hole in center housing (2) and backplate assembly (5). Attach backplate to

center housing with four bolts (21 ) and four locking plates (20). Torque bolts to 13-15 Ib-ft

(18-20 N-m) and bend locking-plate tangs up against side of bolt head.

CAUTION

Do not cock or force piston ring (19) in groove. Ring is brittle and will snap easily.

NOTE

Piston ring (19) is used only on some turbochargers. If there is no groove in shaft, ring

is not required.

(9) Install piston ring (19) on wheel shaft assembly (15).

4-180

|

|