TM9-2815-202-34

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

Do not scuff or scratch bearings when installing shaft or bearing will seize during

operation.

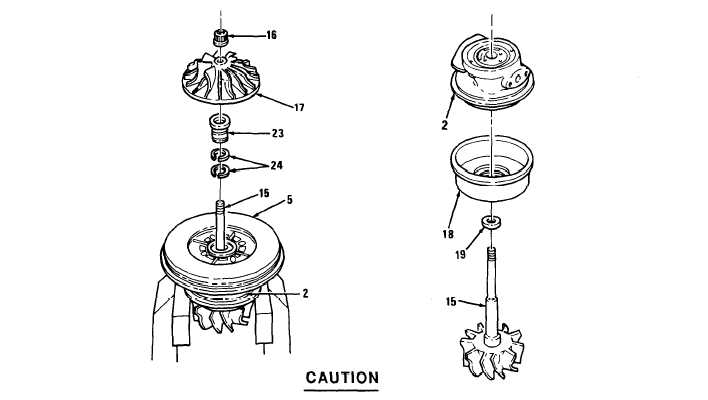

Lubricate wheel shaft assembly (15) with engine oil. Position wheel shroud (18) against

center housing (2). Insert wheel shaft assembly (15) through wheel shroud and into center

housing.

Place wheel shaft assembly (15), shroud (18), center housing (2), and backplate (5) upright

in holding fixture.

CAUTION

Do not cock or force piston rings (24) in grooves. Rings are brittle and will snap easily.

Install two piston rings (24) on thrust spacer (23).

Lubricate thrust spacer (23) and piston rings (24) with engine oil. Slide spacer with rings

over shaft assembly (15) and into bore in backplate (5).

With compressor wheel (17) at 68 -78oF, position it over shaft assembly (15).

Lubricate shaft threads of shaft assembly (15) and wheel face on compressor wheel (17)

with engine oil. Install retaining nut (16). Torque nut to 10-12 Ib-ft (14-17 N-m) to seat

compressor wheel against thrust spacer.

Loosen nut (16) and inspect nut face and front face of compressor wheel to insure they are

smooth and clean.

Tighten nut to 15-25 lb-in (2-3 N-m) torque.

4-181

|

|