|

|

|

|

|

TM 9-2815-202-34

4-37. TURBOCHARGER REPAIR (Cont)

CAUTION

Tighten compressor wheel

turbine wheel shaft.

(18) Tighten nut an additional

nut with a double universal

110 degrees of rotation.

socket to prevent bending

(19) Check bearing axial end play as follows:

(a)

(b)

(c)

Clamp center housing assembly in bench vise equipped with soft jaws.

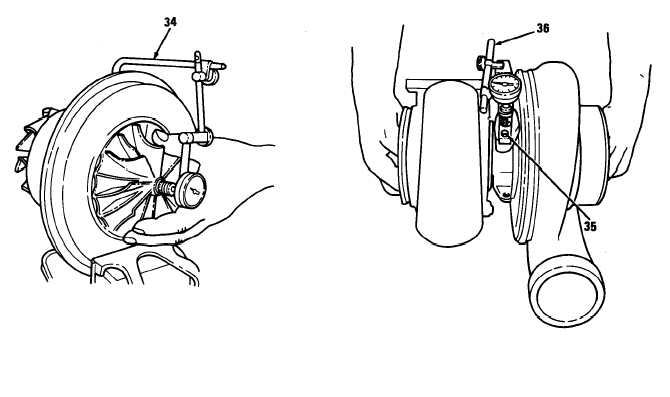

Fasten dial indicator and magnetic base (34) to center housing with indicator tip resting

on end of rotating shaft on compressor side.

Move shaft axially back and forth by hand. Total indicator reading should be between

0.004 and 0.009 inch. Repair or replace shaft assembly if readings do not fall within

limits.

(20) Check shaft radial movement as follows:

(a) Bolt dial indicator adaptor (35) to oil drain tube mounting pad.

(b) Mount dial indicator (36) on dial indicator adaptor (35).

(c) Place dial indicator tip against indicator adaptor rod.

4-182

|

|

|

|

|

Privacy Statement -

Copyright Information. -

Contact Us