TM 9-2815-202-34

4-40. FUEL INJECTOR ASSEMBLY

This task covers:

a. Disassembly

d. Lapping

INITIAL SETUP

MODELS

TOOLS AND SPECIAL TOOLS

General mechanics tooI kit (App B, Item 96)

Injector holding fixture (App B, Item 20)

Spray tip remover (App B, Item 95)

Rack hole cleaning brush (App B, Hem 95)

Pin vise (App B, Item 95)

Spray tip wire (App B, Item 95)

Fuel hole cleaning brush (App B, Item 95)

Injector body reamer (App B, Item 95)

Nut reamer (App B, Item 95)

Nut reamer - tip hole (App B, Item 95)

Spring tester (App B, Item 93)

REPAIR

b. Cleaning

c.

e. Assembly

f.

Inspection/Measurements

Testing

Wire rotary brush (App B, Item 9)

Spray tip carbon remover (App B, Item 95)

Diesel fuel tester (App B, Item 91)

Micrometer (1-2”) (App B, Item 65)

Micrometer (0-1”) (App B, Item 65)

MANDATORY REPLACEMENT PARTS

1 Seal ring (App F, Item 141)

2 Gaskets (App F, Item 77)

.

1 Filter (App F, Item 14)

EXPENDABLE/DURABLE SUPPLIES

Fuel oil (App C, Item 21)

Cleaning solvent (App C, Item 10)

Lapping compound (App C, Item 25)

Engine oil (App C, Item 16)

Needle valve height gage (App B, Item 35)

Torque wrench (App B, Item 101)

Lapping blocks (App B, Item 7)

EQUIPMENT CONDITION

Diesel test fixture (App B, Item 89)

Injector nut socket (App B, Item 95)

Para Description

Injector tip concentricity gage and

4-38 Injectors removed (7083-7395 and

rack freeness tester (App B, Item 92)

7083-7398)

5-37 Injectors removed (7083-7391,

7083-7396 and 7083-7399)

a. Disassembly

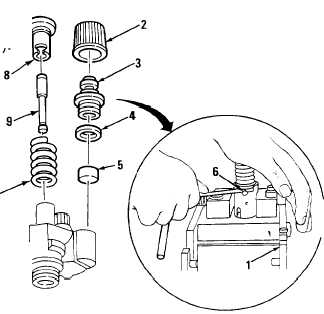

(1) Place injector upright in injector holding fixture

(2) Remove two shipping caps (2), two

fuel line connectors (3), two gaskets

(4), and fuel filter (5) from injector.

Discard filter and gaskets.

(3) Rotate spring until spring end is clear

of pin (6). Compress follower spring

(7) by pressing down on follower (8).

Then raise follower spring above stop

pin (6) with a screwdriver and

withdraw stop pin. Allow spring to rise

gradually by releasing pressure on

follower.

(4) Remove follower (8), follower spring

(7), and plunger (9) from injector as

an assembly.

4-222

Change 1

|

|