TM9-2815-202-34

4-40. FUEL INJECTOR ASSEMBLY

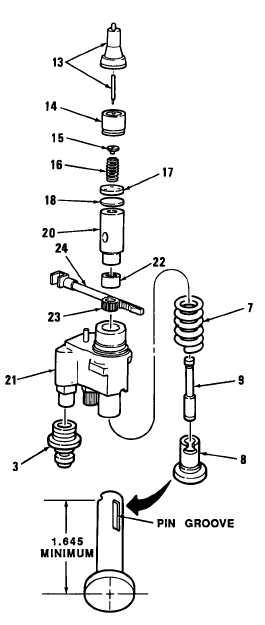

(4) Injector plunger and bushing

REPAIR (Cont)

CAUTION

Make sure high pressure bleed hole in side of bushing is not plugged. If hole is

plugged, fuel oil will leak into engine and cause oil dilution.

NOTE

Keep plunger and bushing together as they are matched sets. Keep parts of each

injector assembly together.

Wash with cleaning solvent and dry with compressed air.

c. Inspection/Measurements

(1) Follower

(a)

(b)

Measure distance between top of

follower (8) and slot. Dimension

must be 1.645 to 1.649 inches.

Inspect stop pin groove in side of

.

follower to make sure it is smooth

and not damaged. Do not reuse

follower if there is more than

0.002 inch wear on top or there is

other visual damage or wear.

(2) Follower spring

(a)

(b)

(c)

Examine outside diameter of

follower spring coils (7) for wear

caused by rocker arms contacting

coils. Replace if worn.

Inspect follower springs for rust,

pitting, nicks, or notches in coils,

broken coils, broken coil ends,

and notches under coil ends.

Check spring tension with spring

tester. Replace spring when a

load of less than 78 Ibs will

compress it to 1.028 inches.

4-226

|

|